Hi guys, I'm relatively new to the Automation field, and I hope to pursue my career in this field.

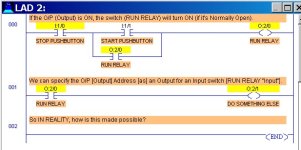

In Ladder Logic programming, we can specify the O/P Address an Output to an Input switch. If the O/P is ON, the switch will turn ON (if it's Normally Open). So IN RELAITY, how is this made possible? Is there a feedback circuit connected from the O/P to the I/P to know the status of the O/P?

And, also, I'm confused with I/P and O/P devices. Some say that Switches are I/P as well as O/P, and relays are I/P as well as O/P. Are external field devices like Motors direct O/Ps of a PLC?

In Ladder Logic programming, we can specify the O/P Address an Output to an Input switch. If the O/P is ON, the switch will turn ON (if it's Normally Open). So IN RELAITY, how is this made possible? Is there a feedback circuit connected from the O/P to the I/P to know the status of the O/P?

And, also, I'm confused with I/P and O/P devices. Some say that Switches are I/P as well as O/P, and relays are I/P as well as O/P. Are external field devices like Motors direct O/Ps of a PLC?