Baker in Virginia

Member

Good Evening ,

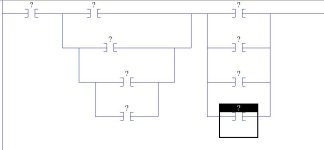

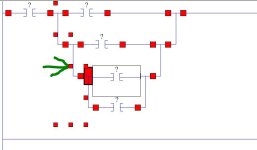

I have a Conveyor system that requires Speed Cascading from one conveyor to another. Meaning that if one conveyor speed is changed , by a HMI pushbutton , that all the others behind it are changed by .1 FPM also.

Attached is an example that I have . It is working , but the operator said when she selected the Cascade HMI Pushbutton to put it in cascade mode , that the FPM jumped from 5.2 FPM to 3.2 FPM. I can't imagine the ONS malfuntioned .

What type of speed cascading systems and programs have you done that are simple and consistant ?

Also , just one more question. I would like to use a Ramp instead of a HMI Pushbutton . When you use a Ramp , and keep your finger on it , the output is still pulses , correct ? If so , these pulses are not too fast for ONS's , correct ?

Thanks so much for your advice ,

I have a Conveyor system that requires Speed Cascading from one conveyor to another. Meaning that if one conveyor speed is changed , by a HMI pushbutton , that all the others behind it are changed by .1 FPM also.

Attached is an example that I have . It is working , but the operator said when she selected the Cascade HMI Pushbutton to put it in cascade mode , that the FPM jumped from 5.2 FPM to 3.2 FPM. I can't imagine the ONS malfuntioned .

What type of speed cascading systems and programs have you done that are simple and consistant ?

Also , just one more question. I would like to use a Ramp instead of a HMI Pushbutton . When you use a Ramp , and keep your finger on it , the output is still pulses , correct ? If so , these pulses are not too fast for ONS's , correct ?

Thanks so much for your advice ,