I have a customer of mine that had any issue with a custom built rod chamfering machine.

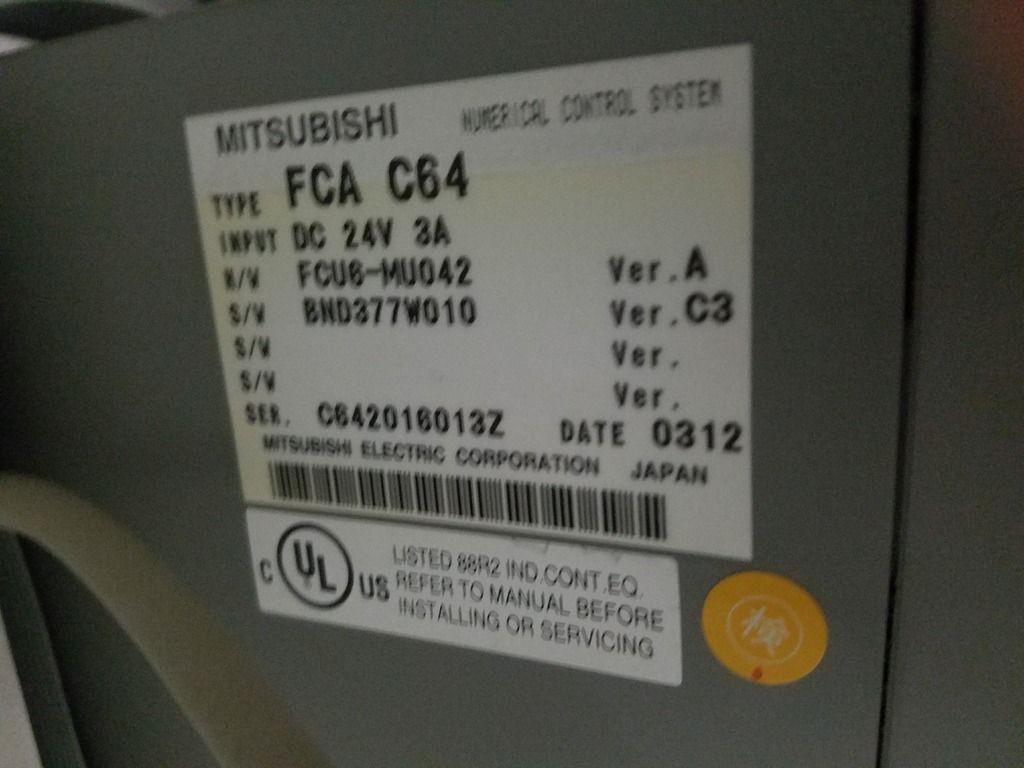

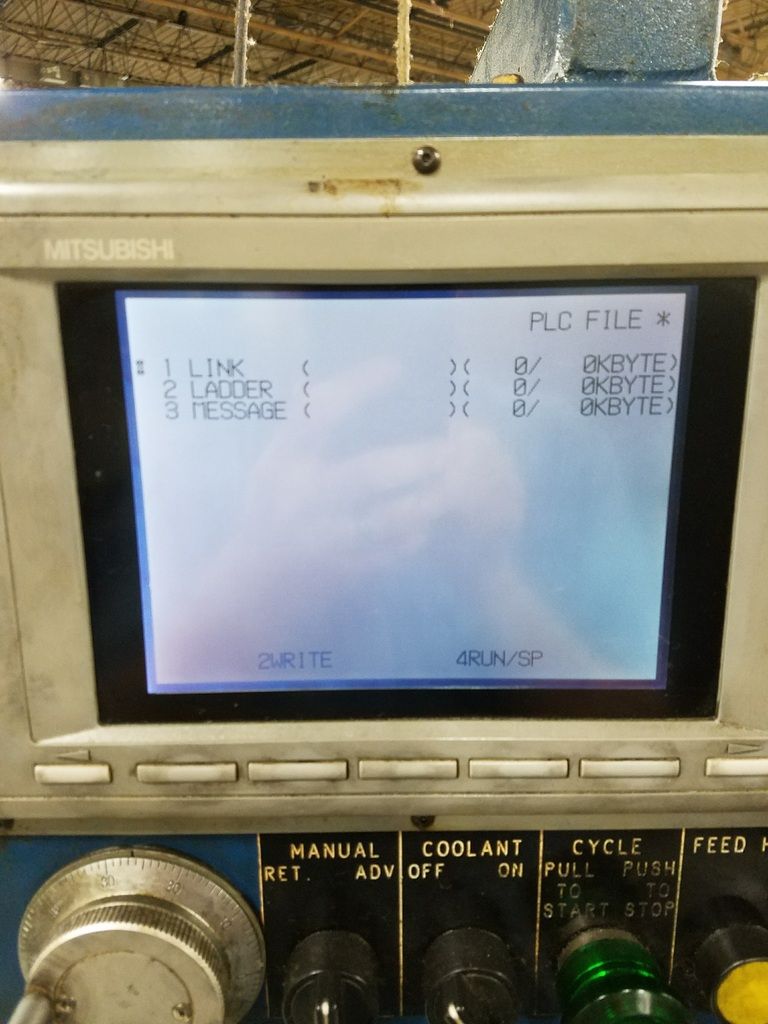

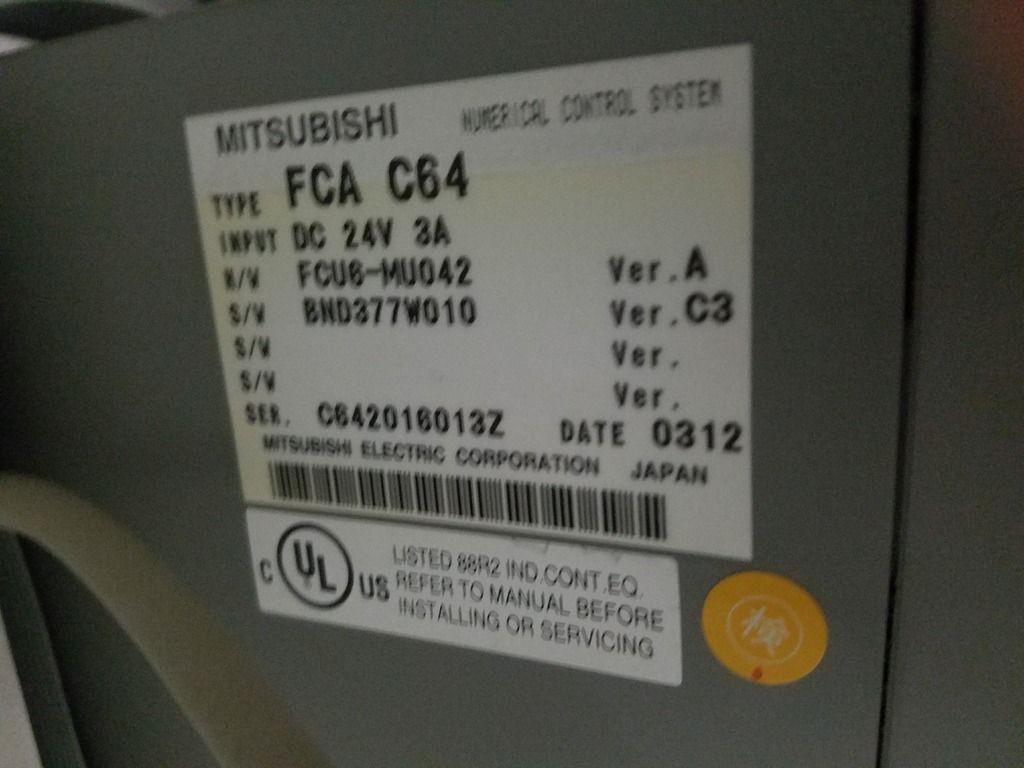

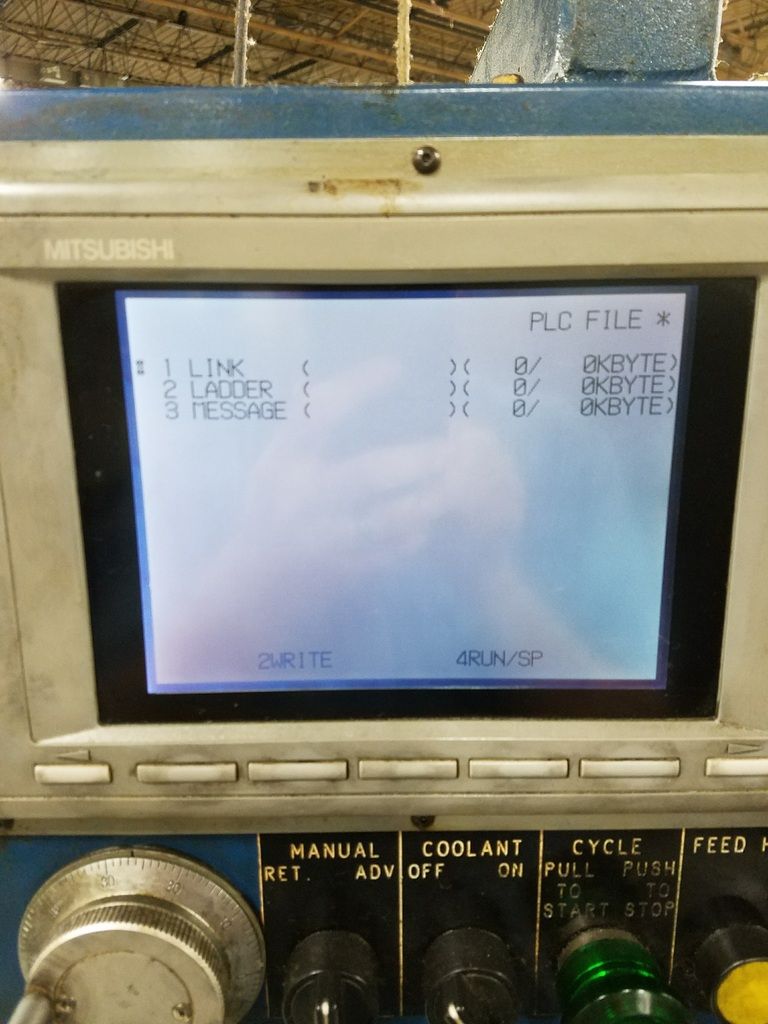

They had a complaint that the CNC would not load. The battery had died and they had not powered the machine up for 6 months. As per mitsubishi tech support suggestion was that there was probably corrupted data in its memory due to the dead battery. I cleared it by turning CS1 switch to 7, power on, power off, CS1 to 0, then power up again. This cleared the memory and the machine loaded with no parameters. I loaded the parameters back into the machine but after further investigation the PLC program is gone.

The machine tool builder, Universal Automatic, went bankrupt and was bought out in 2011. I have contacted the company the purchased them and have gotten all the files they had on the machine, which was not many. They had a few files from the GX developer project. Not sure how they had some and not all. Without a complete project folder I can not make what they got me to make a workable machine.

I am a PLC programmer, electrical control machine repair, retrofit, but I do not have any experience programming this CNC PLC. I have contacted several companies trying to get someone that has knowledge of programming this control but everyone of them are "too busy".

Is there someone on here that knows of or has experience with this CNC control and programming them? The machine is located in Macomb County, Michigan.

The machine seems to be a simple operation. There are two spindles facing each other mounted to a lead screw controlled by a mitsubishi servo drive.

Any more information needed I can try to provide. I do have prints for the machine.

They had a complaint that the CNC would not load. The battery had died and they had not powered the machine up for 6 months. As per mitsubishi tech support suggestion was that there was probably corrupted data in its memory due to the dead battery. I cleared it by turning CS1 switch to 7, power on, power off, CS1 to 0, then power up again. This cleared the memory and the machine loaded with no parameters. I loaded the parameters back into the machine but after further investigation the PLC program is gone.

The machine tool builder, Universal Automatic, went bankrupt and was bought out in 2011. I have contacted the company the purchased them and have gotten all the files they had on the machine, which was not many. They had a few files from the GX developer project. Not sure how they had some and not all. Without a complete project folder I can not make what they got me to make a workable machine.

I am a PLC programmer, electrical control machine repair, retrofit, but I do not have any experience programming this CNC PLC. I have contacted several companies trying to get someone that has knowledge of programming this control but everyone of them are "too busy".

Is there someone on here that knows of or has experience with this CNC control and programming them? The machine is located in Macomb County, Michigan.

The machine seems to be a simple operation. There are two spindles facing each other mounted to a lead screw controlled by a mitsubishi servo drive.

Any more information needed I can try to provide. I do have prints for the machine.