TheJacobsDad

Member

Hi All,

I am in the middle of having a brain **** and hoping you guys can get me back on track.

I have some code in a marshalling PLC (CompactLogix L30ER) which is adjusting the load outputs of generators based on the available fuel which is working fine.

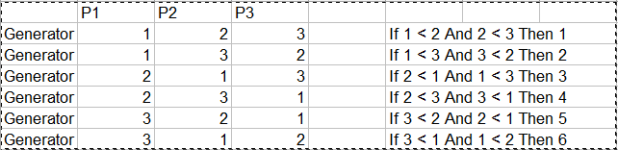

However we now want to introduce a priority system whereby a value from 1-3 is set in an external database (I can read write from this already) and I adjust the generators in order based on this priority value - So if for example Generator 1 is set with a priority of 1 it will increase load first and decrease load last, if however it is a priority 2 then it will wait until the other generators with priority 1 have reached their max load and so on

I am sure there is an elegant solution to this but I currently cant see the wood for the trees.

Any help would be much appreciated

I am in the middle of having a brain **** and hoping you guys can get me back on track.

I have some code in a marshalling PLC (CompactLogix L30ER) which is adjusting the load outputs of generators based on the available fuel which is working fine.

However we now want to introduce a priority system whereby a value from 1-3 is set in an external database (I can read write from this already) and I adjust the generators in order based on this priority value - So if for example Generator 1 is set with a priority of 1 it will increase load first and decrease load last, if however it is a priority 2 then it will wait until the other generators with priority 1 have reached their max load and so on

I am sure there is an elegant solution to this but I currently cant see the wood for the trees.

Any help would be much appreciated