Hey Folks,

I have a question regarding how the CP1E stores its received RS485 data.

Please be easy on my explanation lol, detailed rs485, HEX info and data registers are new to me.

A quick overview of the project, im working on a personal project and experimenting with RS485 communication so I can slowly get comfortable with it, and begin learning how to integrate it into future projects.

Im designing a Generator switchover system using a Omron CP1E-N30DR-D and have a addon CP1W-CIF12 rs485 card, its the same as the CIF11 just with opto isolation. The unit will also have a NB7W HMI that I will remote mount and use it to control and show parameter data, and connect it to the spare fixed RS232 port on the plc.

With that I have a simple 4ch current and voltage module that can sense current on 4 feeds, and voltage on 4 feeds, and sends the data over the RS485 line once it is asked by the PLC.

I learned and slowly figured out how to get the module and PLC to talk, and now I have continuous data flowing between the 2, I wrote a simple program that writes the required bits to the D1300 to D1305 memory registers, and sends it away to the power module. The PLC sends the read register command ( 01 03 00 00 00 28 45 D4).

In response the Power Module sends back ( 01 03 50 02 74 00 78 01 C2 00 01 18 04 00 00 00 03 06 00 00 00 00 00 00 00 00 00 0B B8 03 E8 00 00 00 00 00 00 00 00 00 00 00 00 0B B8 03 E8 00 00 00 00 00 00 00 00 00 00 00 00 0B B8 03 E8 00 00 00 00 00 00 00 00 00 00 00 00 0B B8 03 E8 00 00 00 00 01 D6 00)

Which is fine, I have the data sheet that describes what the HEX bits are, and im working on how to convert them to useable decimal values.

Im using a RS485 to usb adaptor mid line to view the send and receive data between the 2.

Now here's my problem.

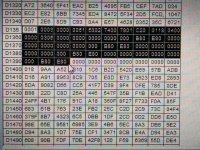

This data gets dumped into the data registers D1350 to D1399, but there doesn't look to be enough space to store it all. D1400 and on, has a bunch of other random data. Is there anything I can do to utlize all the data being sent back. Although I only need 4ch of Amps, and 4ch of Volts, there are also many other channels of data such as Hz, Watts, and PFC.

Any help would be greatly appreciated

I have a question regarding how the CP1E stores its received RS485 data.

Please be easy on my explanation lol, detailed rs485, HEX info and data registers are new to me.

A quick overview of the project, im working on a personal project and experimenting with RS485 communication so I can slowly get comfortable with it, and begin learning how to integrate it into future projects.

Im designing a Generator switchover system using a Omron CP1E-N30DR-D and have a addon CP1W-CIF12 rs485 card, its the same as the CIF11 just with opto isolation. The unit will also have a NB7W HMI that I will remote mount and use it to control and show parameter data, and connect it to the spare fixed RS232 port on the plc.

With that I have a simple 4ch current and voltage module that can sense current on 4 feeds, and voltage on 4 feeds, and sends the data over the RS485 line once it is asked by the PLC.

I learned and slowly figured out how to get the module and PLC to talk, and now I have continuous data flowing between the 2, I wrote a simple program that writes the required bits to the D1300 to D1305 memory registers, and sends it away to the power module. The PLC sends the read register command ( 01 03 00 00 00 28 45 D4).

In response the Power Module sends back ( 01 03 50 02 74 00 78 01 C2 00 01 18 04 00 00 00 03 06 00 00 00 00 00 00 00 00 00 0B B8 03 E8 00 00 00 00 00 00 00 00 00 00 00 00 0B B8 03 E8 00 00 00 00 00 00 00 00 00 00 00 00 0B B8 03 E8 00 00 00 00 00 00 00 00 00 00 00 00 0B B8 03 E8 00 00 00 00 01 D6 00)

Which is fine, I have the data sheet that describes what the HEX bits are, and im working on how to convert them to useable decimal values.

Im using a RS485 to usb adaptor mid line to view the send and receive data between the 2.

Now here's my problem.

This data gets dumped into the data registers D1350 to D1399, but there doesn't look to be enough space to store it all. D1400 and on, has a bunch of other random data. Is there anything I can do to utlize all the data being sent back. Although I only need 4ch of Amps, and 4ch of Volts, there are also many other channels of data such as Hz, Watts, and PFC.

Any help would be greatly appreciated

Last edited: