Hello everyone,

I am trying to use port 2 on a Click PLC to send a few simple commands to a third party servo drive over RS232. I need to send four consecutive bytes to the drive to run the motor at a constant speed. For my testing, I am using the send command to send ($7F), ($8A), ($BC), ($C5) to the drive but I'm not having any luck. I have verified that the port settings match the drive requirements.

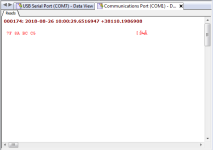

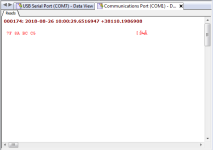

The servo drive does exactly what I want when using the test software that was supplied with it, so I used a serial port monitoring software to verify what was being sent to the drive. It shows each byte on a separate line.

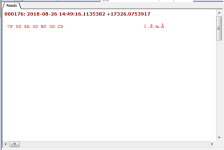

When I send the same data using the Click, the serial monitor shows everything on one line. I have tried using one send command with all four bytes and I have tried separate send commands, each enabled by the previous command's "success" bit.

Anyone have any ideas? I'm not very experienced with serial communications so any help is greatly appreciated!

I am trying to use port 2 on a Click PLC to send a few simple commands to a third party servo drive over RS232. I need to send four consecutive bytes to the drive to run the motor at a constant speed. For my testing, I am using the send command to send ($7F), ($8A), ($BC), ($C5) to the drive but I'm not having any luck. I have verified that the port settings match the drive requirements.

The servo drive does exactly what I want when using the test software that was supplied with it, so I used a serial port monitoring software to verify what was being sent to the drive. It shows each byte on a separate line.

When I send the same data using the Click, the serial monitor shows everything on one line. I have tried using one send command with all four bytes and I have tried separate send commands, each enabled by the previous command's "success" bit.

Anyone have any ideas? I'm not very experienced with serial communications so any help is greatly appreciated!