swedeleaner

Member

Hey guys!!

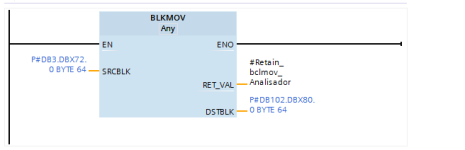

I have never used ANY-pointers or configured larger areas to be moved.

As you see, i want to copy whats inside DB1, 256 byte long and send to Q256.

Q256 is an Anybus-module. (It has to be configured but just want to confirm that the data is sent correctly)

I have no chance to test it right now, and the compiler seems to like it.

Is this how you copy large amounts of data between different areas in TIA Portal?

I have never used ANY-pointers or configured larger areas to be moved.

As you see, i want to copy whats inside DB1, 256 byte long and send to Q256.

Q256 is an Anybus-module. (It has to be configured but just want to confirm that the data is sent correctly)

I have no chance to test it right now, and the compiler seems to like it.

Is this how you copy large amounts of data between different areas in TIA Portal?