Hello,

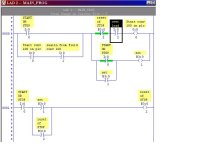

I have a SLC5/05 and am having problems writing code for a pushbutton (momentary) to start and stop a process.

The problem is this... Due to a fast scan time, the pushbutton can be energized through the scan several times. Even when putting in a single debounce timer, I cannot figure out how to get it to work correctly because it always comes back around and either keeps the process latched or unlatched, depending on the last rung of logic.

I have a bit that latches (1) and the process will start. When that bit unlatches (0), the process ends.

The pushbutton should both latch and unlatch (start and stop) the process.

This has got to be a simple thing. Anyone out there know a quick answer?

I have a SLC5/05 and am having problems writing code for a pushbutton (momentary) to start and stop a process.

The problem is this... Due to a fast scan time, the pushbutton can be energized through the scan several times. Even when putting in a single debounce timer, I cannot figure out how to get it to work correctly because it always comes back around and either keeps the process latched or unlatched, depending on the last rung of logic.

I have a bit that latches (1) and the process will start. When that bit unlatches (0), the process ends.

The pushbutton should both latch and unlatch (start and stop) the process.

This has got to be a simple thing. Anyone out there know a quick answer?