Please confirm which drives you are seeing this fault code on: PowerFlex 70, PowerFlex 700, or PowerFlex 40 ? Your posts have not been clear about that.

As my colleague jraef has pointed out, a fault code "71" has a slightly different meaning on the PowerFlex 40 than it does on the PowerFlex 70/700.

On the PowerFlex 40, the LED display "F71" indicates a "net loss" fault, which does indicate noise or loss of signal on the DeviceNet. This is distinct from the fault "F81" that indicates a loss of connection on the ribbon cable between the 22-COMM-D module and the PowerFlex main control board.

On the PowerFlex 70/700, the "- Fault - F 71" display indicate that there's been a communication failure between the device on DPI Port 1 and its network. This is distinct from the "- Fault - F 81" code that would appear if the device on DPI Port 1 stopped talking to the drive or was unplugged.

"DPI" is the "Drive Peripheral Interface" protocol and wiring that PowerFlex 70/700 drives use to connect to network modules and keypad "HIM" modules. The DPI port number is based on where the device is physically plugged into the drive.

On PowerFlex 70/700 drives, DPI Port 1 is the onboard HIM cradle. DPI Port 5 is the 20-COMM-D module.

It should not be possible to get a "- Fault - F 71" fault related to the DeviceNet interface on a PowerFlex 70/700 drive. That would be fault code 75, not 71.

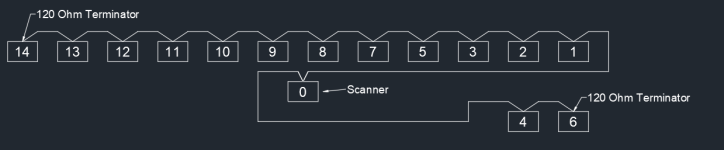

If this is a system that lacked proper termination, it is probable that it also has other wiring problems like a noisy power supply or loose connectors. The DeviceNet cable planning and installation guide has good information on how to properly power a DeviceNet and install the wiring.