ronny_resistor

Member

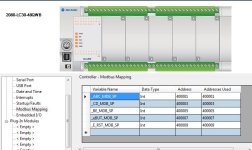

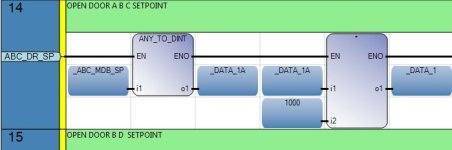

I have a Allen Bradley Micro850 that was supposed to be able to communicate with ethernet to my PARKER SSD 690+ Ethernet Board. (Does this quite well in Controllogix L23 Platform). Anyway spent a day looking at this with Ethernet and decided to try Modbus TCP as the Ethernet Module is able to communicate Via both Ethernet and Modbus TCP (The device is an HMS Ethernet card).

I have attached what the manufacturer has provided and I am not sure if I am missing something here. Anyone well versed in the Micro850 and is able to help ??

I have the current file but my zip upload is pegged at <400 The file is 600Kb [email protected] I can send you the file if that would help.

I have attached what the manufacturer has provided and I am not sure if I am missing something here. Anyone well versed in the Micro850 and is able to help ??

I have the current file but my zip upload is pegged at <400 The file is 600Kb [email protected] I can send you the file if that would help.