Hey all,

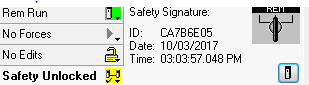

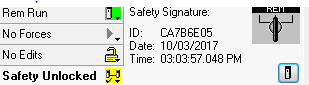

I cannot edit the safety rotines in rslogix 500 1764 L43S compact logix. I am able to edit the standard routines but the safety task. The controller was safety locked . I have unlocked and now the status is safety unlock with signature. How can I edit the routines. Do I have the makes changed offline and download the program or there is any other way to do this . Please find the attache ments Kindly help.

I cannot edit the safety rotines in rslogix 500 1764 L43S compact logix. I am able to edit the standard routines but the safety task. The controller was safety locked . I have unlocked and now the status is safety unlock with signature. How can I edit the routines. Do I have the makes changed offline and download the program or there is any other way to do this . Please find the attache ments Kindly help.