Ones_Zeros

Member

Hello,

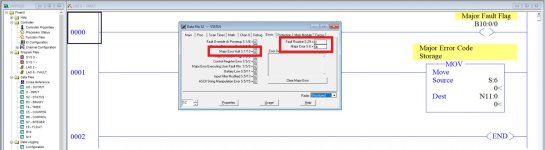

I have a SLC500 Micrologix PLC that will sometimes go into a "Watchdog fault"

When it does this all the data on the wonderware screen is frozen and appears to be real until someone catches it on site.

My question is if the PLC is faulted is there a way that I can still read this fault into the wonderware so that a operator can catch it early or does a faulted PLC cut off all comminutions to the controller?

thanks,

I have a SLC500 Micrologix PLC that will sometimes go into a "Watchdog fault"

When it does this all the data on the wonderware screen is frozen and appears to be real until someone catches it on site.

My question is if the PLC is faulted is there a way that I can still read this fault into the wonderware so that a operator can catch it early or does a faulted PLC cut off all comminutions to the controller?

thanks,