Hi all my expert friends...I'm still new with Siemens PLC and I am using the Siemens PLC model S7-300 (CPU315-2 DP). I am facing some programming issues as follows:

1) The PID configuration - The PID action is not correct. Its action is at only one way even when the PV > SP or PV < SP. What's the most proper method to configure the PID? I'm using the FB41 CONT_C function block.

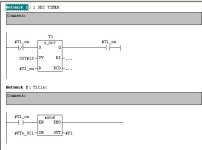

2) I need to do some program to detect actual time of 1 sec. But the Sec Timer used in program unable to detect accurately 1 sec (compare to actual time of 1 second). Any configuration or method to avoid this?

PLZ...can any of our experts help me oUT ASAP? PLZZ..

Thank you.. <"o">..

1) The PID configuration - The PID action is not correct. Its action is at only one way even when the PV > SP or PV < SP. What's the most proper method to configure the PID? I'm using the FB41 CONT_C function block.

2) I need to do some program to detect actual time of 1 sec. But the Sec Timer used in program unable to detect accurately 1 sec (compare to actual time of 1 second). Any configuration or method to avoid this?

PLZ...can any of our experts help me oUT ASAP? PLZZ..

Thank you.. <"o">..