M15cell

Member

Hello everyone,

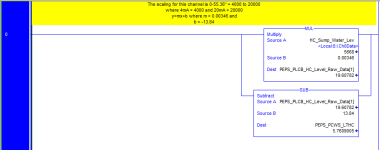

I have a plc 5 input card receiving an input from a conductivity

Transmitter where 0ma=0 uhms and 20ma= 20,000 uhms

The raw min is 0 and Max is 4095, I’m not very familiar with plc 5 but I understand there’s no SCP option.

What would be the best way of scaling this in the ladder logic?

Thank you for your help.

I have a plc 5 input card receiving an input from a conductivity

Transmitter where 0ma=0 uhms and 20ma= 20,000 uhms

The raw min is 0 and Max is 4095, I’m not very familiar with plc 5 but I understand there’s no SCP option.

What would be the best way of scaling this in the ladder logic?

Thank you for your help.