bharathchari1

Member

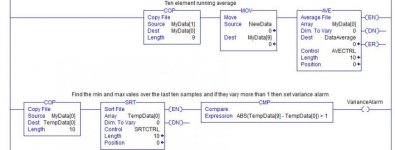

I have an AB PLC where I am trying to read analog values to see if the values vary more than 1V in 5 minutes? I have 10 sets of values I need to read. What would the easiest way to implement this? I can think of creating arrays to save the values each time I read them but the part I am having trouble with is, how to keep a running average of the values and compare against each time I read them.

Any help with this would be greatly appreciated!!

Any help with this would be greatly appreciated!!