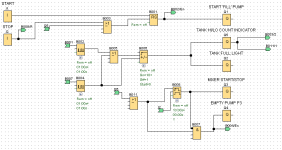

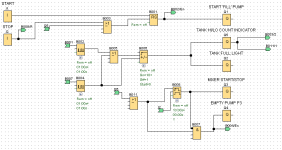

I've downloaded the demo version of the LOGO software and here is my interpretation of your requirement. Posting the complete spec for your tank fill/mix/empty would be better.

Thanks for your help, i actually managed it in the same way you have done, but using the pulse relay instead. I am pretty certain i had tried with the latch relay as you have done but it wouldnt stop the "empty pump" from running as it was supposed to. i am guessing i had something else connected wrong.

fyi.. here was the spec.. (ignore the numbering for the function blocks, im guessing they are what was used by whoever made the assessment paper)

"

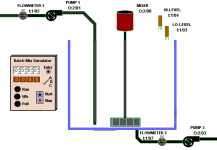

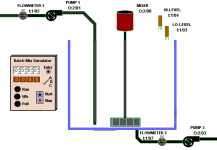

The application above illustrates a simple stirring application in a lemonade factory.

a) Use LOGO to design and build the above system, using function block or ladder logic, which will control the operation as follows:

• When the Start ‘push to make’ (not toggle) switch (I1) is pressed/released, and gets latched on (B1: RS latch), the start ‘fill’ pump (Q1) will be energized and the tank will start to fill.

• The pulses generated by flow meter 1 (B5: pulse generator) should be used to increment the counter (B6: Up/down). Tank level full is when the counter function on = 10 and tank low level is when counter off = 1. These values can be used as feedback to control the pumps (instead of the high/low level sensors shown above) and can be called the ‘tank high/low level count indicator’ (Q5 or use a flag M1)

• When the full liquid level in the tank is sensed by the tank high/low level count indicator (Q5), the fill pump will be shut-off and the FULL light (Q2) on the control panel is to be energized.

• When the tank is full, start the mixer (Q3) and run for 10 seconds (B8: off-delay timer).

• When the 10 seconds has expired, stop the mixer (Q3) and start ‘empty’ pump P3 (Q4).

• Pump 3 (Q4) will be required to run until the tank is empty. Tank empty can be detected using the low-level sensor (I3).

• The pulses generated by flow meter 3 (B15) should be used to decrement the counter (B6: Up/down). Tank empty can be detected by the high/low level count indicator (Q5 or use a flag M1) to switch off the pump

• When the stop button (I2) is operated, the process must stop immediately (Q1, Q3, Q4).

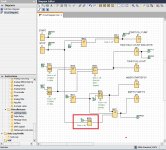

b) Test your LOGO build and comment on your testing using LOGO simulation mode. This requires at least 3 print-screens of testing the system using the LOGO simulator below at the filling, mixing and emptying stages

c) Save your program and email a copy of your program along with your assessment.

Guidance: Clearly snip/print-screen and explain your build and test work. Use input/output (I/Q) numbers shown. Function numbers (B) can be your own choice, and you are also likely to need some basic logic functions (e.g. And/Or/Not) for the various conditions given in 3a. "