rsdoran

Lifetime Supporting Member

I am working on upgrading another sealer type machine, this one is automatic now but uses all relay logic. Recently a woman got her hand caught between the jaws of the sealer and the cut block, it didnt complete its cycle so it didnt heat/cut but it also had mechanical issues which made it stay in position holding her hand which in turn did cause a minor burn from the residual heat.

Anyway as the machine was designed (had to be half a century ago) it didnt use any form of ESTOP and the STOP circuit isnt what I call normal. I will see about scanning the schematics and if any would like to see them I will email.

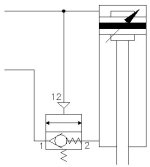

What I plan is to build a new cabinet (the existing is on the floor and an oven has to be moved to access it). The main voltage is 240v single phase so I originally planned on using a Master Control Relay and the ESTOP plus safety limits completing that circuit that but have now considered using a Safety Relay..would that make more sense?

OR just let the ESTOP control a Master Relay which kills all power and let the safety limit switches on the cutting arm just cause the system to HALT its cycle and return to start position? With the safety relay scenario the cutting arm should also return to its start/home position. Another issue is that they have to pull cello thru the cutting space at times (new roll etc) so need to be able to feed the cello, I thought it would make more sense to add a jog/feed button to feed the cello for this purpose instead of cycling the machine as it is done now.

I also plan to use either an ATD system or create one with the plc but my primary concern is make sure that if any obstruction stops the cutting head from coming down for more than X secs(or 10ths of a sec) that the cycle halts and goes to home. I dont have a way to make it stay in place and do not want it to stay down, down is the only scenario I can see that may cause any harm.

The rest of the system is fairly straightforward..product comes down conveyor is detected then pusher places it under cutter then cutter head comes down heats/seals then conveyor moves it away to oven.

My company is on a safety thing (which I have no problem with) and my main concern is doing this properly. I want the machine to be as safe as possible. I am working now on some drawings for this but I keep changing them because of the above issues.

I have a GE Fanuc 90-30 (with the firmware upgraded recently) 5 slot with enough I/O options to do anything I need with this small system.

I also plan to modify the cutting head to lower its home position and change the rams involved to use MRS (magnetic reed switches) to show position. The head has none at this time, just limit switches to show when down and pusher also uses limit switches. Would it be more practical to use MRS over mechanical limit switches? I am hoping to increase the machines auto cycle time from 20 pcs a minute to 60 pcs a minute....I know probably biting off more than I can chew.

BTW this thing now uses Electromechanical timers (4) for dwell, heat etc and I hope to replace them with the PLC and use some form of HMI to allow them to set times if needed. I think with the PLC and if I create the right timing features with pulses I can maintain the arm at a consistent point so that it would be very rare if timing needed changed much...there will always be situations like heavier cello..thinner etc. Your recommendations on a simple HMI that works well with the GE 90-30 would be appreciated.

Again I appreciate any answers that are given.

Anyway as the machine was designed (had to be half a century ago) it didnt use any form of ESTOP and the STOP circuit isnt what I call normal. I will see about scanning the schematics and if any would like to see them I will email.

What I plan is to build a new cabinet (the existing is on the floor and an oven has to be moved to access it). The main voltage is 240v single phase so I originally planned on using a Master Control Relay and the ESTOP plus safety limits completing that circuit that but have now considered using a Safety Relay..would that make more sense?

OR just let the ESTOP control a Master Relay which kills all power and let the safety limit switches on the cutting arm just cause the system to HALT its cycle and return to start position? With the safety relay scenario the cutting arm should also return to its start/home position. Another issue is that they have to pull cello thru the cutting space at times (new roll etc) so need to be able to feed the cello, I thought it would make more sense to add a jog/feed button to feed the cello for this purpose instead of cycling the machine as it is done now.

I also plan to use either an ATD system or create one with the plc but my primary concern is make sure that if any obstruction stops the cutting head from coming down for more than X secs(or 10ths of a sec) that the cycle halts and goes to home. I dont have a way to make it stay in place and do not want it to stay down, down is the only scenario I can see that may cause any harm.

The rest of the system is fairly straightforward..product comes down conveyor is detected then pusher places it under cutter then cutter head comes down heats/seals then conveyor moves it away to oven.

My company is on a safety thing (which I have no problem with) and my main concern is doing this properly. I want the machine to be as safe as possible. I am working now on some drawings for this but I keep changing them because of the above issues.

I have a GE Fanuc 90-30 (with the firmware upgraded recently) 5 slot with enough I/O options to do anything I need with this small system.

I also plan to modify the cutting head to lower its home position and change the rams involved to use MRS (magnetic reed switches) to show position. The head has none at this time, just limit switches to show when down and pusher also uses limit switches. Would it be more practical to use MRS over mechanical limit switches? I am hoping to increase the machines auto cycle time from 20 pcs a minute to 60 pcs a minute....I know probably biting off more than I can chew.

BTW this thing now uses Electromechanical timers (4) for dwell, heat etc and I hope to replace them with the PLC and use some form of HMI to allow them to set times if needed. I think with the PLC and if I create the right timing features with pulses I can maintain the arm at a consistent point so that it would be very rare if timing needed changed much...there will always be situations like heavier cello..thinner etc. Your recommendations on a simple HMI that works well with the GE 90-30 would be appreciated.

Again I appreciate any answers that are given.