backendcode

Member

Hello Guys,

I am working on my first real world project to control the conveyor system. The control panel has PLC, terminal block for the proximity sensor and motor contactor with motor overload and of course other components of control panel such as power supply, transformer etc and I don't think as a PLC programmer I need to care more about those components.

Question: As a PLC programmer, What factors I need to consider about contractors and motor overload

Here is info about my contractors:-

MOTOR CONTACTOR 10AMPS 24VDC LOW CONSUMPTION COIL 1NO AUXILIARY CONTACT

Here is the info about my motor overload

OVERLOAD RELAY 0.8-1.2A 1NO AND 1NC AUXILIARY CONTACT

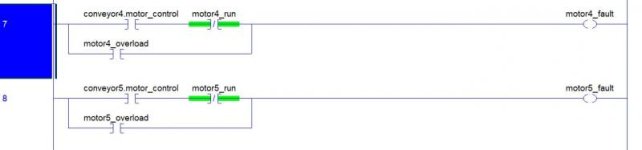

The control panel drawing also shows there is feedback going to PLC input card for each motor run and motor overload. Am I going to use the status of those input addresses to find the fault in motor and motor overload and turn on the fault indicator light and stop the light until someone will reset the fault I guess?

What is the purpose of this feedback going to PLC input card and what is the purpose of contractors auxiliary contact (Which is normally open) and auxiliary contact of motor overload(1 NO, 1NC)

Please help me to understand the purpose of this information provided?

Thank you!

I am working on my first real world project to control the conveyor system. The control panel has PLC, terminal block for the proximity sensor and motor contactor with motor overload and of course other components of control panel such as power supply, transformer etc and I don't think as a PLC programmer I need to care more about those components.

Question: As a PLC programmer, What factors I need to consider about contractors and motor overload

Here is info about my contractors:-

MOTOR CONTACTOR 10AMPS 24VDC LOW CONSUMPTION COIL 1NO AUXILIARY CONTACT

Here is the info about my motor overload

OVERLOAD RELAY 0.8-1.2A 1NO AND 1NC AUXILIARY CONTACT

The control panel drawing also shows there is feedback going to PLC input card for each motor run and motor overload. Am I going to use the status of those input addresses to find the fault in motor and motor overload and turn on the fault indicator light and stop the light until someone will reset the fault I guess?

What is the purpose of this feedback going to PLC input card and what is the purpose of contractors auxiliary contact (Which is normally open) and auxiliary contact of motor overload(1 NO, 1NC)

Please help me to understand the purpose of this information provided?

Thank you!