lbric

Member

Hello,

i am new to this forum but have checked in many times before for helpful tips but now decided to register to get some help of my own.

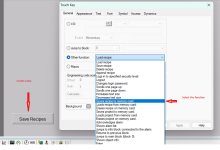

i have a few questions, first being: i am writting a program to control 2 motors in a mix tank. in the program i have a subroutine that is my mix cycle and in the main program i have the sequence that calls the mix cycle 5 times. in each step of my sequence, i have a move function that drops the run time into a RTO in the subroutine for the cycle. the main program resets the RTO after each cycle and places the new run time at the start of the next cycle. i have formulas that have different run times, can i use the RCP configuration file and RCP instruction to create a selectable database that can call up a formula and its run times? would it be done by storing integers that can be placed in the source parameter of the mov function when the recipe is called?

question 2: i am using rslogix micro starter lite and a micrologix 1100 plc for this project. what software would i need to create a HMI for this program with an AB panelview plus screen? would i be able to make a screen that has all my formulas where i would be able to select one and have its run times drop into the main program that runs my mix tank?

last question: besides using AB HMI are there affordable screens with affordable software that i would be able to use? i beleive that the AB software can get rather expensive.

thanks in advance

lbric

i am new to this forum but have checked in many times before for helpful tips but now decided to register to get some help of my own.

i have a few questions, first being: i am writting a program to control 2 motors in a mix tank. in the program i have a subroutine that is my mix cycle and in the main program i have the sequence that calls the mix cycle 5 times. in each step of my sequence, i have a move function that drops the run time into a RTO in the subroutine for the cycle. the main program resets the RTO after each cycle and places the new run time at the start of the next cycle. i have formulas that have different run times, can i use the RCP configuration file and RCP instruction to create a selectable database that can call up a formula and its run times? would it be done by storing integers that can be placed in the source parameter of the mov function when the recipe is called?

question 2: i am using rslogix micro starter lite and a micrologix 1100 plc for this project. what software would i need to create a HMI for this program with an AB panelview plus screen? would i be able to make a screen that has all my formulas where i would be able to select one and have its run times drop into the main program that runs my mix tank?

last question: besides using AB HMI are there affordable screens with affordable software that i would be able to use? i beleive that the AB software can get rather expensive.

thanks in advance

lbric