Hello Everyone,

To get started I am a Mech. Engineer and am trying to self-teach myself how to program for a home project. That being said I don’t have a lot of examples to go by and I am hoping that my question is easy and is just something I haven't seen or know to try yet. That being said I will try and explain the best I can. Basically I have two sensors and a solenoid valve controlling a hydraulic motor. When sensor one sees its flag I am turning the hydraulic motor on until it rotates enough for sensor two sees its flag. The problem I run into is that the flag for sensor 1 is mechanically driven based on ground speed. If I happen to be going too slow or stop and that flag is still in front of the sensor, as the plc continues to cycle and it "sees" that this flag is made and continues to rotate the motor. Is there a way to program this so that sensor one has to reset itself, as in it has to turn off(not see the flag) and then see the flag again before the motor is allowed to rotate and index the flag for sensor two again?

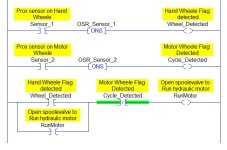

As you can see in the attachment I have tried using a drum for this. Sensor one is "1 unit count" and sensor two is "1 cup count". I tried adding a timer in step one to give the flag time to move off of sensor one. This only works so well though and I am not happy with how it works.

I have tried a bunch of different methods including not using a drum sequencer and just cannot seem to wrap my head around this. If anyone has the time to hold my hand through this it would be greatly appreciated.

Thanks,

Derek

*Edit* Also I should note I am using a Productivity 2000 plc from automation direct for this project.

To get started I am a Mech. Engineer and am trying to self-teach myself how to program for a home project. That being said I don’t have a lot of examples to go by and I am hoping that my question is easy and is just something I haven't seen or know to try yet. That being said I will try and explain the best I can. Basically I have two sensors and a solenoid valve controlling a hydraulic motor. When sensor one sees its flag I am turning the hydraulic motor on until it rotates enough for sensor two sees its flag. The problem I run into is that the flag for sensor 1 is mechanically driven based on ground speed. If I happen to be going too slow or stop and that flag is still in front of the sensor, as the plc continues to cycle and it "sees" that this flag is made and continues to rotate the motor. Is there a way to program this so that sensor one has to reset itself, as in it has to turn off(not see the flag) and then see the flag again before the motor is allowed to rotate and index the flag for sensor two again?

As you can see in the attachment I have tried using a drum for this. Sensor one is "1 unit count" and sensor two is "1 cup count". I tried adding a timer in step one to give the flag time to move off of sensor one. This only works so well though and I am not happy with how it works.

I have tried a bunch of different methods including not using a drum sequencer and just cannot seem to wrap my head around this. If anyone has the time to hold my hand through this it would be greatly appreciated.

Thanks,

Derek

*Edit* Also I should note I am using a Productivity 2000 plc from automation direct for this project.