celichi

Lifetime Supporting Member

Hello Ladies and Gents,

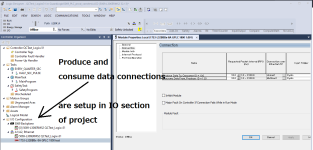

I have some PLC to PLC communications using Produce and Consume.

The data is not time sensitive, and I really only need a turn around of 1-2 seconds.

The current program has RPI set to 20ms, this seems overkill to me.

The IT group is saying that there is a lot of traffic (+200K packets in 5 minutes).

My instinct is telling me that 20ms is way to zippy for this, and I would like to set this to 1000 ms.

Am I heading in the right direction?

Also, can this be changed online in run, or do I have to save/upload --> go offline --> change RPI --> download.

Thanks in advance,

I have some PLC to PLC communications using Produce and Consume.

The data is not time sensitive, and I really only need a turn around of 1-2 seconds.

The current program has RPI set to 20ms, this seems overkill to me.

The IT group is saying that there is a lot of traffic (+200K packets in 5 minutes).

My instinct is telling me that 20ms is way to zippy for this, and I would like to set this to 1000 ms.

Am I heading in the right direction?

Also, can this be changed online in run, or do I have to save/upload --> go offline --> change RPI --> download.

Thanks in advance,