Scenario is robotic cell that stacks pallets onto conveyors. Conveyors move stacks of pallets out of cell to pickup location. Cell is fenced except across outfeed conveyor in question where a light curtain is used to guard.

System is using a Safety PLC and standard practice would be to use muting sensors wired to safety inputs to control muting of Light Curtain when pallets feed out.

Question I've been asked is if we can omit the sensors and use PLC non-safety rated output turned on when Conv running to mute Light Curtain?

My gut tells me know but we have multiple robotic cells built by other OEMs in our facilities who are using programmatic muting.

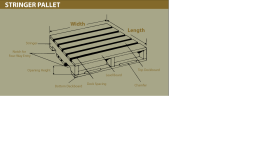

The reason it's being questioned is because space is tight and I'm having trouble finding sensing solutions for muting that will not be prone to seeing through the holes in pallets and can be places close together.

Any insight into the programmatic muting or people who've had good success with a particular sensing strategy for seeing pallets continuously as they convey by is much appreciated!

System is using a Safety PLC and standard practice would be to use muting sensors wired to safety inputs to control muting of Light Curtain when pallets feed out.

Question I've been asked is if we can omit the sensors and use PLC non-safety rated output turned on when Conv running to mute Light Curtain?

My gut tells me know but we have multiple robotic cells built by other OEMs in our facilities who are using programmatic muting.

The reason it's being questioned is because space is tight and I'm having trouble finding sensing solutions for muting that will not be prone to seeing through the holes in pallets and can be places close together.

Any insight into the programmatic muting or people who've had good success with a particular sensing strategy for seeing pallets continuously as they convey by is much appreciated!