justin lutz

Member

Good Friday evening, everyone!

I have been struggling for a about a week now, trying to tune this loop.

Background:

There are two control loops. One is existing (programmed by someone else) and one is new (being programmed by myself).

Loop #1, Existing Loop:

PV: Dissolved Oxygen (D.O.) (as measured in Aeration Basin)

SP: D.O. setpoint entered at HMI

CV: Inlet Air Valve to Aeration Basin (0 - 70%)

Update Time: 120 seconds

This loop modulates the Inlet Air Valve to allow more/less air to the basin in order to maintain a D.O. setpoint. I have confirmed that this loop does appear to work well. Note: There are actual 3 separate loops here, one for each aeration basin/D.O. analyzer/inlet valve. However, the new loop that I am programming is only influenced by one of these loops at a time (the one with the most open valve).

Loop #2, New Loop:

PID Info:

PLC-5

ISA Equation

Error: PV - SP

PV: Most Open Valve (Valve %)

SP: Hard-coded at 40%

CV: Blower (45-100%)

Update time: 240 seconds

This loop ramps the blower throughput up and down in order to keep the most open basin inlet valve (there are three of these, one for each basin) operating at 40% open.

Breakdown of the Process:

The two loops essentially fight eachother.

In the first loop, as the D.O. decreases below its respective setpoint, the basin inlet valve modulates open to allow more air to increase the D.O. reading. This can oocur for all 3 basins simultaneously, although that is not always the case.

In the second loop, once the most open of the 3 valves exceeds the most open valve setpoint of 40%, the blower begins to ramp up (the blower is always running at a minimum of 45% when the valves are below 40% open).

With the blower ramping up and the inlet valve open to the basin, the D.O. level begins to increase. Once the D.O. level exceeds the setpoint, the valve for that basin begins to modulate closed. As the valve begins to modulate closed, the blower then ramps down because it is being told that the air demand is decreasing for that basin.

Problems/Observations:

What I am constantly seeing here is that my blower (Loop #2 CV) is waiting too long to decrease when the most open valve (Loop #2 PV) has already begun its decrease. As time goes on and this continues, the valve is driven closed by Loop #1 faster and faster because too much air is being provided by the blower. It seems to me that the update time has some influence on this, because just as Loop #1 (update time 120 sec) begins driving the valve closed, Loop #2 (update time 240 sec) continues to ramp the blower up (when I REALLY want it to ramp DOWN). I have tried assigning the same update time to Loop #2, but the same issue occurs. Meanwhile, a choked-down valve and a ramped up blower create another problem called high header pressure.

So, my goal here is the following:

- Do not alter existing Loop #1 in any way, since it is not broken and I do not wish to fix it.

- Refine new Loop #1 such that the blower modulates to allow the most open valve to track the setpoint of 40% open.

- Do not exceed the high header pressure of 7.10 psi

The PID terms:

Kc is fairly straight forward to me.

Ti is giving me some trouble. Per Ron's "WhatIsI" document, the integral term is defined as the length of time it takes for the integralaction to repeat the proportional action. So, my PID only executes once every 240 seconds. How does the integral term figure into this? If I enter the I term into the configuration as 70, that translates to (70*0.01) or 0.7 minutes per repeat. That equates to a repeat of every 42 seconds, if I am understanding this correctly. So, does the value that you use for the I term have to be less than your loop update time?? Furthermore, if you have an I term defined that would result in several repeats within the loop update time, does it just update the one time when the rung goes true or...??

Td - I know a lot of folks say you don't need this for most applications. I currently am not using it. However, I used the PID loop tuning pocket guide by control soft, which recommends using Td for slow loops. I would consider my loop to be a slow one, so maybe this would help me out?

Using the open and closed loop tuning procedures in the guide, i arrived at the following intial settings for my PID:

Kc = 167

Ti = 200

Td = 0

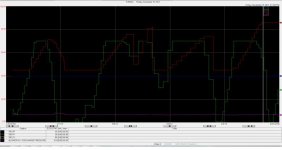

Right from the get-go, given what i have described about the process so far, do these seem viable or do they seem extraordinarily out of whack? I have since adjustedd my Kc and Ti based on recommendations given in the pocket guide and I am now at Kc = 135 and Ti = 70. Please see the attached trend (4th PID execution all the way on the right) showing what these values are giving me.

Green = PV (most open valve)

Blue = SP (40%)

Red = CV (blower throuput, 45-100%)

At first, I thought I was on the right track because my CV increments were small and steady, however as you can see in the 4th ramp up on the trend, the CV just continued to take off.

I have been hammering away at this for almost a week. I don't want to resort to trial-and-error, but frustration is getting the best of me. Can anyone make some recommendations as to what I should be doing with my gain and/or reset time, loop update time and whether or not I should be using the derivative rate term?

My apologies for the long winded post. I am trying to be detailed without being confusing. Hopefully I have found some success in my attempt.

Thank you in advance for any comments or advice that you might have!

Justin

I have been struggling for a about a week now, trying to tune this loop.

Background:

There are two control loops. One is existing (programmed by someone else) and one is new (being programmed by myself).

Loop #1, Existing Loop:

PV: Dissolved Oxygen (D.O.) (as measured in Aeration Basin)

SP: D.O. setpoint entered at HMI

CV: Inlet Air Valve to Aeration Basin (0 - 70%)

Update Time: 120 seconds

This loop modulates the Inlet Air Valve to allow more/less air to the basin in order to maintain a D.O. setpoint. I have confirmed that this loop does appear to work well. Note: There are actual 3 separate loops here, one for each aeration basin/D.O. analyzer/inlet valve. However, the new loop that I am programming is only influenced by one of these loops at a time (the one with the most open valve).

Loop #2, New Loop:

PID Info:

PLC-5

ISA Equation

Error: PV - SP

PV: Most Open Valve (Valve %)

SP: Hard-coded at 40%

CV: Blower (45-100%)

Update time: 240 seconds

This loop ramps the blower throughput up and down in order to keep the most open basin inlet valve (there are three of these, one for each basin) operating at 40% open.

Breakdown of the Process:

The two loops essentially fight eachother.

In the first loop, as the D.O. decreases below its respective setpoint, the basin inlet valve modulates open to allow more air to increase the D.O. reading. This can oocur for all 3 basins simultaneously, although that is not always the case.

In the second loop, once the most open of the 3 valves exceeds the most open valve setpoint of 40%, the blower begins to ramp up (the blower is always running at a minimum of 45% when the valves are below 40% open).

With the blower ramping up and the inlet valve open to the basin, the D.O. level begins to increase. Once the D.O. level exceeds the setpoint, the valve for that basin begins to modulate closed. As the valve begins to modulate closed, the blower then ramps down because it is being told that the air demand is decreasing for that basin.

Problems/Observations:

What I am constantly seeing here is that my blower (Loop #2 CV) is waiting too long to decrease when the most open valve (Loop #2 PV) has already begun its decrease. As time goes on and this continues, the valve is driven closed by Loop #1 faster and faster because too much air is being provided by the blower. It seems to me that the update time has some influence on this, because just as Loop #1 (update time 120 sec) begins driving the valve closed, Loop #2 (update time 240 sec) continues to ramp the blower up (when I REALLY want it to ramp DOWN). I have tried assigning the same update time to Loop #2, but the same issue occurs. Meanwhile, a choked-down valve and a ramped up blower create another problem called high header pressure.

So, my goal here is the following:

- Do not alter existing Loop #1 in any way, since it is not broken and I do not wish to fix it.

- Refine new Loop #1 such that the blower modulates to allow the most open valve to track the setpoint of 40% open.

- Do not exceed the high header pressure of 7.10 psi

The PID terms:

Kc is fairly straight forward to me.

Ti is giving me some trouble. Per Ron's "WhatIsI" document, the integral term is defined as the length of time it takes for the integralaction to repeat the proportional action. So, my PID only executes once every 240 seconds. How does the integral term figure into this? If I enter the I term into the configuration as 70, that translates to (70*0.01) or 0.7 minutes per repeat. That equates to a repeat of every 42 seconds, if I am understanding this correctly. So, does the value that you use for the I term have to be less than your loop update time?? Furthermore, if you have an I term defined that would result in several repeats within the loop update time, does it just update the one time when the rung goes true or...??

Td - I know a lot of folks say you don't need this for most applications. I currently am not using it. However, I used the PID loop tuning pocket guide by control soft, which recommends using Td for slow loops. I would consider my loop to be a slow one, so maybe this would help me out?

Using the open and closed loop tuning procedures in the guide, i arrived at the following intial settings for my PID:

Kc = 167

Ti = 200

Td = 0

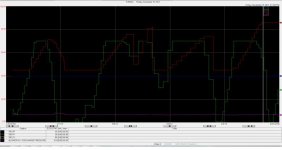

Right from the get-go, given what i have described about the process so far, do these seem viable or do they seem extraordinarily out of whack? I have since adjustedd my Kc and Ti based on recommendations given in the pocket guide and I am now at Kc = 135 and Ti = 70. Please see the attached trend (4th PID execution all the way on the right) showing what these values are giving me.

Green = PV (most open valve)

Blue = SP (40%)

Red = CV (blower throuput, 45-100%)

At first, I thought I was on the right track because my CV increments were small and steady, however as you can see in the 4th ramp up on the trend, the CV just continued to take off.

I have been hammering away at this for almost a week. I don't want to resort to trial-and-error, but frustration is getting the best of me. Can anyone make some recommendations as to what I should be doing with my gain and/or reset time, loop update time and whether or not I should be using the derivative rate term?

My apologies for the long winded post. I am trying to be detailed without being confusing. Hopefully I have found some success in my attempt.

Thank you in advance for any comments or advice that you might have!

Justin