Hello Experts,

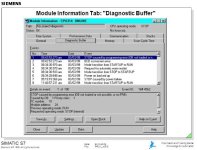

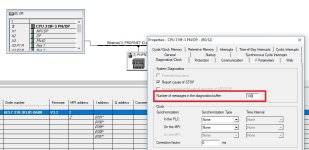

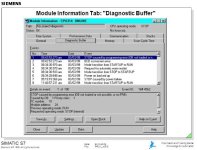

I would like to seek advise on how or what tag i should use or do to get the PLC diagnostic buffer to know what is the root cause of the current PLC faults from Siemens S7-400 PLCs? We are having PLC system fault instantaneously but at random times and i cannot be on site 24/7 to standby and wait for the issue to show. So i am thinking to get the text description of the fault from the controller so operators can feed me the information. Maybe i can put in alarms description or save it in a notepad with triggering bit from HMI. Save as .csv file. Detailed help would be wonderful, i havent done this yet. thanks!

Control system specs:

Simatic Manager v5.5

InTouch v11

I would like to seek advise on how or what tag i should use or do to get the PLC diagnostic buffer to know what is the root cause of the current PLC faults from Siemens S7-400 PLCs? We are having PLC system fault instantaneously but at random times and i cannot be on site 24/7 to standby and wait for the issue to show. So i am thinking to get the text description of the fault from the controller so operators can feed me the information. Maybe i can put in alarms description or save it in a notepad with triggering bit from HMI. Save as .csv file. Detailed help would be wonderful, i havent done this yet. thanks!

Control system specs:

Simatic Manager v5.5

InTouch v11