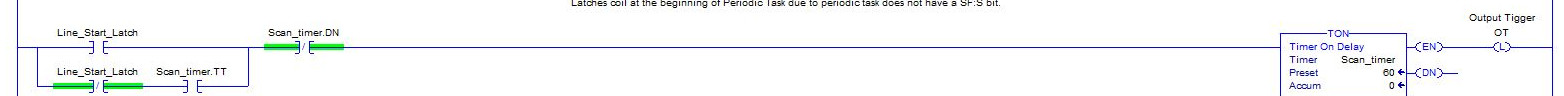

I currently running a compact logix 1769-L33ER 20.11. I have a functioning periodic task that runs every 100ms, using rslogix 5000.

This task is currently bringing in an analog value, doing some conversions and filing a FIFO array to ave then outputting to hmi and control system. It is a total of 9 lines.

Now we are expanding on the project. I am adding 4 more analog values which I need to do the same instances with.

My question is should I create separate periodic tasks or try to arrange all instance in the same periodic task?

I need to execute these analog values the same way to send to the tension system. Guidance to writing the code correctly for better flow and execution would greatly help me learn.

I figured I could created arrays and place all in compact memory locations for like TAGS.

This task is currently bringing in an analog value, doing some conversions and filing a FIFO array to ave then outputting to hmi and control system. It is a total of 9 lines.

Now we are expanding on the project. I am adding 4 more analog values which I need to do the same instances with.

My question is should I create separate periodic tasks or try to arrange all instance in the same periodic task?

I need to execute these analog values the same way to send to the tension system. Guidance to writing the code correctly for better flow and execution would greatly help me learn.

I figured I could created arrays and place all in compact memory locations for like TAGS.