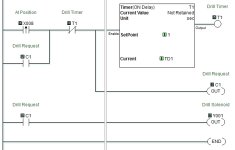

I need to write a program for an Automation Direct Click PLC to drill a lot of holes (50-100) with a self feed drill. I will have two common inputs to the PLC of "saw parked" (X115)from a Prox sensor and a "at position" (X008) signal from the servo drive. The common output from the PLC to drill the hole will be the same for every hole, Y001 to the solenoid valve for one second. The only way I've found so far is to use a set and reset command for the internal bit for each hole which is not at all practical since that would be about 6-10 lines for every hole. I know the "double coil sysdrum" is taboo but that would be perfect(?) because the program is not going to see the Y001 unless it's at a hole location. I can see the problem with the double coil sysdrum, especially with internal C bits but.....

Any ideas on how to make this program and programing time shorter?

Any ideas on how to make this program and programing time shorter?