There we go. A picture speaks 1000 words!

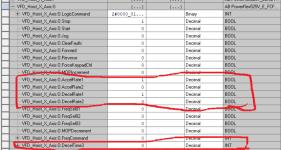

AccelRate1 and AccelRate2 as you say are BOOL tags, which you turn on or off to select whether the drive uses AccelTime1 or AccelTime2. I now understand that you are using the PLC to switch between AccelTime1 and AccelTime2, which are fixed times, programmed into the VSD, by writing a one or a zero to the AccelRate1 and AccelRate2 BOOL tags.

You have then tried to enable the selection of AccelTime3, which is again a fixed time programmed into the drive. However, after following the advice you received, you added a datalink which gave you access to AccelTime3, not AccelRate3.

So, where to from here? I'm not sure of a way to get the AccelRate3 BOOL tag into the PLC over ethernet. It may not be possible without getting into some in-depth explicit messaging. The reason for this (if it is indeed the case)is likely because it's far simpler to do what I described previously - dynamically change your AccelTime in the PLC, rather than having two or three fixed AccelTime's and using two or three AccelRate's to select them.

So, my advice would be:

1. Record the values for AccelTime1, 2 and 3 from the VSD parameters. For this example, let's assume that the times are 1000ms, 5000ms, and 8000ms respectively.

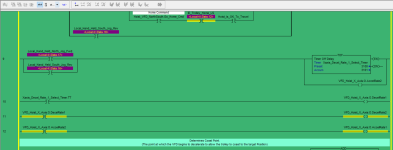

2. Find the PLC logic that sets the OTE's for AccelRate1, AccelRate2 and your work-in-progress AccelRate3

3. Change the datalink in your drive setup from AccelTime3 to AccelTime1

4. Modify the logic so that where AccelRate1 was previously selected, you now instead simply move 1000ms (or whatever) into AccelTime1

5. Modify the logic so that where AccelRate2 was previously selected, you now instead simply move 5000ms (or whatever) into AccelTime1

5. Modify the logic so that where AccelRate3 was previously selected, you now instead simply move 8000ms (or whatever) into AccelTime1

6. Modify the logic to so that the drive always uses AccelTime1 (e.g. unconditional OTE addressed to AccelRate1)

7. Repeat for Decel tags

8. ???

9. Profit!

Two notes:

1. Make sure when you change the datalink in your VSD setup within the PLC, that you also change the respective VSD parameter to match

2. The value you send to the VSD for the ramp time is not in milliseconds. Some scaling will be required, e.g. divide by 10 or multiply by 10. I can't remember the exact figures off the top of my head - it's something I set up once a long time ago in an AOI and have never had to look at again. Easiest way to work it out is to just send a test value e.g. 12345 down to the drive and see how it shows up in the drive, then adjust your scaling accordingly.