i have a Clx(1756-L73) as the main plc, and it is swapping data with Mlx 1500. The two are connected to a AB managed switch(EMS04T). The mlx 1500's connected to eth by a 1761-net-eni module. based from another thread, i can only read messages.

"Controllogix - Setup an SLC Typed Read message pointing to the Data Table address you wish to read, specify the length and destination. The Communications tab is where you specify your path. It will be the name of your ENBT module, 2, then the IP Address. So if your ENBT is named myenbt and your IP Address is 123.123.123.123 your path will be myenbt,2,123.123.123.123

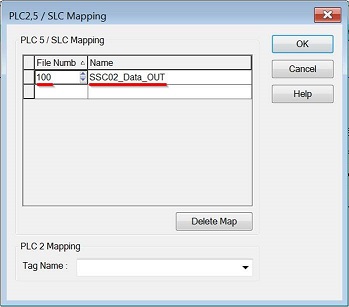

Micrologix - You will setup routing in the ENI from the Controllogix IP Address to a node on the serial side. This must be node 45-49 for a Controllogix and the Controllogix processor must reside in slot 0. From there your must map the tag to SLC/PLC5 tag, and setup a 500CPU Read message in the Micrologix pointing to the data address you specified in your mapping and the node address configured in the ENI"

so am I correct up until this part?here you can see the msg in the Clx and Mlx

http://www.flickr.com/photos/76004776@N06/7140563437/in/photostream

"Controllogix - Setup an SLC Typed Read message pointing to the Data Table address you wish to read, specify the length and destination. The Communications tab is where you specify your path. It will be the name of your ENBT module, 2, then the IP Address. So if your ENBT is named myenbt and your IP Address is 123.123.123.123 your path will be myenbt,2,123.123.123.123

Micrologix - You will setup routing in the ENI from the Controllogix IP Address to a node on the serial side. This must be node 45-49 for a Controllogix and the Controllogix processor must reside in slot 0. From there your must map the tag to SLC/PLC5 tag, and setup a 500CPU Read message in the Micrologix pointing to the data address you specified in your mapping and the node address configured in the ENI"

so am I correct up until this part?here you can see the msg in the Clx and Mlx

http://www.flickr.com/photos/76004776@N06/7140563437/in/photostream

Last edited: