Im installing a level sensor and cannot get it to work. this is the sensor:

https://cache.industry.siemens.com/dl/files/141/45351141/att_5659/v1/7ML19985KQ01.pdf

In terminal 1 I have connected +24Vdc and in terminal 2 the plc input, however when I put the sensor under water or product the signal never changes, I always measure the same voltaje between terminal 1 and 2. However the light changes from green to red..

What could be the problem ??

I saw that the datasheet says this, what does it mean that is not suitable for low voltaje plc input ?? that it wont work ? why ??

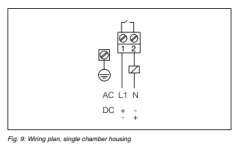

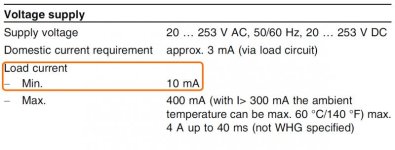

Warning:

The instrument must not be operated without an intermediately

connected load, because the electronics would be destroyed if

connected directly to the mains. It is not suitable for connection

to low voltage PLC inputs.

For direct control of relays, contactors, magnet valves, warning

lights, horns etc.

Domestic current is temporarily lowered below 1 mA after

switching off the load so that contactors, whose holding current

is lower than the constant domestic current of the electronics,

are reliably switched off.

Thanks in advance !!

https://cache.industry.siemens.com/dl/files/141/45351141/att_5659/v1/7ML19985KQ01.pdf

In terminal 1 I have connected +24Vdc and in terminal 2 the plc input, however when I put the sensor under water or product the signal never changes, I always measure the same voltaje between terminal 1 and 2. However the light changes from green to red..

What could be the problem ??

I saw that the datasheet says this, what does it mean that is not suitable for low voltaje plc input ?? that it wont work ? why ??

Warning:

The instrument must not be operated without an intermediately

connected load, because the electronics would be destroyed if

connected directly to the mains. It is not suitable for connection

to low voltage PLC inputs.

For direct control of relays, contactors, magnet valves, warning

lights, horns etc.

Domestic current is temporarily lowered below 1 mA after

switching off the load so that contactors, whose holding current

is lower than the constant domestic current of the electronics,

are reliably switched off.

Thanks in advance !!