Hello all,

Well I am back. I have been using and learning a lot about the SLC500 and I am able to use the Input / Out cards / Analog In / Out cards and I have done a lot. I have used the advanced HIM interface.

I would like to thank you all but now I have 1 battle where I need some help.

The 1746-HSTP1

Okay,

I have the following:

SLC500 Card - 1746-HSTP1

Stepper Motor - AXHM015K-30 (http://www.airlinehyd.com/APOLLO/ORIENTAL/AXH.PDF)

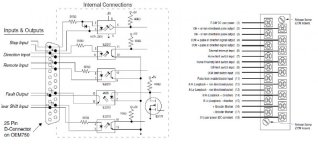

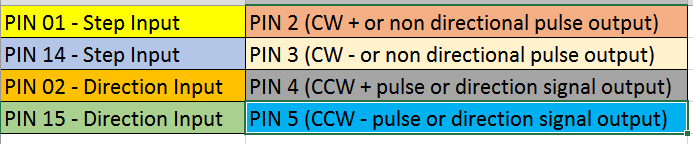

Driver - OEM750 http://www.parkermotion.com/manuals/OEM750/OEM750_Entire_Rev_B.pdf

So, I have the following, I saved up for a few months to buy this and now I need to set it up.

I understand that people can say, just go a learn. I have but, I feel that I need to approach this part with caution as I do not want to blow up anything.

Here are some of the objectives:

Thank you all and I really need you help with this one.

Please note, I am not working for a company, I am doing this just to expand my mind.

Thank you

Well I am back. I have been using and learning a lot about the SLC500 and I am able to use the Input / Out cards / Analog In / Out cards and I have done a lot. I have used the advanced HIM interface.

I would like to thank you all but now I have 1 battle where I need some help.

The 1746-HSTP1

Okay,

I have the following:

SLC500 Card - 1746-HSTP1

Stepper Motor - AXHM015K-30 (http://www.airlinehyd.com/APOLLO/ORIENTAL/AXH.PDF)

Driver - OEM750 http://www.parkermotion.com/manuals/OEM750/OEM750_Entire_Rev_B.pdf

So, I have the following, I saved up for a few months to buy this and now I need to set it up.

I understand that people can say, just go a learn. I have but, I feel that I need to approach this part with caution as I do not want to blow up anything.

Here are some of the objectives:

- Wire up the stepper motor to the driver

- Wire up the driver to the stepper card

- make a simple program to step the motor

Thank you all and I really need you help with this one.

Please note, I am not working for a company, I am doing this just to expand my mind.

Thank you