You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

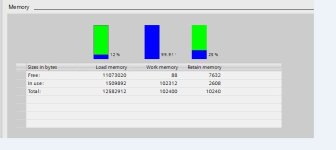

Siemens S7-1200 Work Memory

- Thread starter exiled

- Start date

I don't think there is a "Compress" function like there is in an S7-400.

You could potentially try factory resetting the PLC and downloading again, but I'm not sure how much it would help.

I THINK that the PLC gets "compressed" whenever you reinitialize the DBs, but I'm not sure.

You could potentially try factory resetting the PLC and downloading again, but I'm not sure how much it would help.

I THINK that the PLC gets "compressed" whenever you reinitialize the DBs, but I'm not sure.

JRW

Member

Please tell us you didn’t buy a 1211 and are trying to do recipes etc etc etc

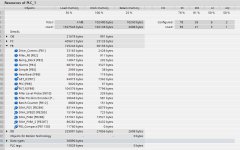

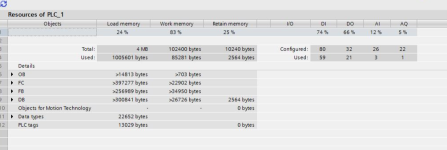

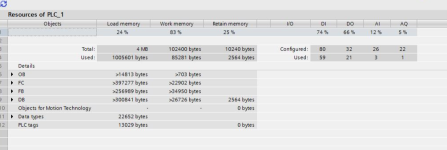

The plc is a 1214C. We did have to add a CP module a few years back and I must admit this looks like where all the work memory is been used.

Just wondered if you guys knew any work arounds.

What do you suggest I put in its place a LOGO?

Just wondered if you guys knew any work arounds.

Please tell us you didn’t buy a 1211 and are trying to do recipes etc etc etc

What do you suggest I put in its place a LOGO?

You need to compress program or change bigger CPU.

Since FB's are multiused, I would think that it would be easier to check FC side if there is same FC -blocks which could be changed to FB/DB and save little bit memory.

Also Karnaught mappping and ST-coding helps save memory.

And if there is calculations, maybe you can change them so that not all is calculated on same program scan.

Would it use then less work memory, since not all code is executed at one scan cycle

Easiest would be change to bigger 1200 or 1512 CPU series

Since FB's are multiused, I would think that it would be easier to check FC side if there is same FC -blocks which could be changed to FB/DB and save little bit memory.

Also Karnaught mappping and ST-coding helps save memory.

And if there is calculations, maybe you can change them so that not all is calculated on same program scan.

Would it use then less work memory, since not all code is executed at one scan cycle

Easiest would be change to bigger 1200 or 1512 CPU series

You need to compress program or change bigger CPU.

Since FB's are multiused, I would think that it would be easier to check FC side if there is same FC -blocks which could be changed to FB/DB and save little bit memory.

Also Karnaught mappping and ST-coding helps save memory.

And if there is calculations, maybe you can change them so that not all is calculated on same program scan.

Would it use then less work memory, since not all code is executed at one scan cycle

Easiest would be change to bigger 1200 or 1512 CPU series

I think it would be difficult to convince the customer to upgrade the cpu as its been in for a few years now. I have started to condense the program by removing functions that they don't use etc.

Interested in moving some maths around. what is the theory behind that?

TIA

I think it would be difficult to convince the customer to upgrade the cpu as its been in for a few years now.

I was going to ask earlier about you considering a LOGO!!! Didn't quite get that.

What is the PLC firmware and are there processes that can be moved to an I-Device perhaps with some of the modules?

Interested in moving some maths around. what is the theory behind that?

TIA

Work memory is where PLC runs programs, not sure if all blocks are moved to work memory at once, or is it optimized only for blocks which are needed.

At least dividing maths to several scans can make program scan faster.

Anyway, it is nowadays usually not needed, as CPUs have better performance than many years or decades ago.

The CPU fw is 4.1 and the project is written in V13 and as suspected the customer wont upgrade the cpu.

So i've been experimenting by removing some functions that they don't use to try and condense the program with some success.

I decided to do another experiment with version upgrades. going from V13 to V14 makes a huge difference. So i think this will be the easiest way to go with no loss in functionality.

Moving on I think we should be using a 1500 instead of the 1200 platform

So i've been experimenting by removing some functions that they don't use to try and condense the program with some success.

I decided to do another experiment with version upgrades. going from V13 to V14 makes a huge difference. So i think this will be the easiest way to go with no loss in functionality.

Moving on I think we should be using a 1500 instead of the 1200 platform

janner_10

Lifetime Supporting Member

The CPU fw is 4.1 and the project is written in V13 and as suspected the customer wont upgrade the cpu.

Surely thats cheaper than paying for your time trying to cram extras into a plc that is undersized.

A 1215 lists at £545, minus 25% or so is £400, spend a morning on it and its cheaper to just get a new plc, with a bit of headroom for future proofing.

Similar Topics

Hi all,

On my project I have a TP1200 Comfort Panel (6AV2 124-0MC01-0AX0). Unfortunately I don't get to see the hardware until I get to site.

I...

- Replies

- 1

- Views

- 4,445

Is there ANY way to expand the memory on a 1200?

I have maxed out the memory and went as far as passing memory back and forth from working memory...

- Replies

- 1

- Views

- 3,110

commentaire communiqué siemens s7-1200 avec vfd delta ? (cablage et sur tia portal )

- Replies

- 0

- Views

- 84

Hi, I have a 1214 on ip 192.168.0.100. This is connected to other modules through a switch on same network. I need to connect this to a company...

- Replies

- 1

- Views

- 140

Hi Experts,

I would like to make firmware upgrade from v3.0 to v4.5 (S7-1200 CPU 1215C).

Can I do it from v3.0 to v4.5?

Do I need to take some...

- Replies

- 6

- Views

- 210