I’m trying to perfect the HMI interface for analog configuration. I’ve provided the user the same options for all analog inputs, as follows.

Best regards,

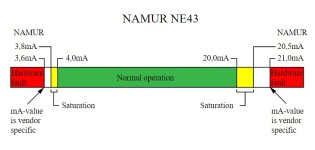

- Lower Calibration Value = 4mA

- Upper Calibration Value = 20mA

- On the PLC, force the value to 0? For me it’s nice to see the negative value, for troubleshooting, but it messes up the alarm settings.

- I’ve thought about using the 0-20mA? (and losing a few bits of resolution).

Best regards,