I_Automation

Lifetime Supporting Member

Just had the anomaly.

Stamping press, 20 years old, SLC5/04 CPU with EEPROM memory module.

The customer says suddenly a couple days ago they have to hold the run buttons down or as soon as they let go it top stops.

DH+ to a PanelMate HMI at 204K baud and the DF-1 port is set to ASCII. Took a while to get an old laptop with the PCMK card connected to the DH+.

Had to upload the use file as it didn't match their last save. Searching through there is a bit that is set if any of a dozen conditions or faults come true to OTE the top stop bit true.

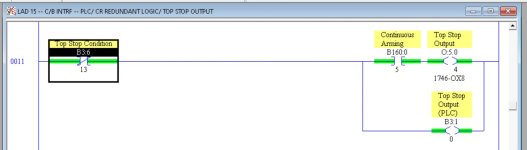

However, the rung that turns on the top stop output for the relay is checking XIO top stop bit, and the saved archive is XIC top stop bit.

Can't online edit through DH+ and can't download to the CPU even if it is in Program by the key - RSLogix says it can't get ownership of the CPU. Pulled the battery & wiped the program with the EEPROM removed and still couldn't connect to the DF-1 port. Put the EEPROM back in and it reloaded the glitched bit, so the XIC changed in the EEPROM and was put in the CPU.

The only recourse I had was get another 5/04, change channel 1 to System and 19,200 baud and download the program to it to have the correct program and be able to use the DF-1 port.

Stamping press, 20 years old, SLC5/04 CPU with EEPROM memory module.

The customer says suddenly a couple days ago they have to hold the run buttons down or as soon as they let go it top stops.

DH+ to a PanelMate HMI at 204K baud and the DF-1 port is set to ASCII. Took a while to get an old laptop with the PCMK card connected to the DH+.

Had to upload the use file as it didn't match their last save. Searching through there is a bit that is set if any of a dozen conditions or faults come true to OTE the top stop bit true.

However, the rung that turns on the top stop output for the relay is checking XIO top stop bit, and the saved archive is XIC top stop bit.

Can't online edit through DH+ and can't download to the CPU even if it is in Program by the key - RSLogix says it can't get ownership of the CPU. Pulled the battery & wiped the program with the EEPROM removed and still couldn't connect to the DF-1 port. Put the EEPROM back in and it reloaded the glitched bit, so the XIC changed in the EEPROM and was put in the CPU.

The only recourse I had was get another 5/04, change channel 1 to System and 19,200 baud and download the program to it to have the correct program and be able to use the DF-1 port.