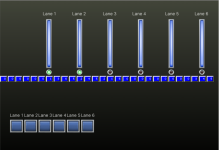

I still prefer the integer, and only one shift register I think it's cleaner, I would use only integers so you could have hundreds of lines, also, if like the one I did for a sortation system you can split the word into nibbles or bytes or both then have more information like I did for example lower byte was bar code (although it was a simple one 1-999), use the two upper nibbles for things like overweight, no bar code read or anything else.

The system I did started at pick stations 8 I believe, a box was packed with components in each pick area, these ran into lifts to a high level conveyor, these boxes were mixed i.e. filtered into the one line and sent to the sortation area, here they were sorted into 17 possible lanes, a reject lane and sent back to the start of the sort if no bar code read, 3 times & then rejected, the boxes were stored on the 17 lanes each lane would have a code for that stores requirement (entered by the controller), the 17 lanes would accumulate the required number of boxes when the pick for that consignment was complete the lane would release them and mix with others down to the next floor where again they were sorted into 6 lanes & stackers ready for moving into the lorries, seems a bit daft sorting then mixing then sorting but logistically made sense to make full use of the time and lorry loading slots.

The system I did started at pick stations 8 I believe, a box was packed with components in each pick area, these ran into lifts to a high level conveyor, these boxes were mixed i.e. filtered into the one line and sent to the sortation area, here they were sorted into 17 possible lanes, a reject lane and sent back to the start of the sort if no bar code read, 3 times & then rejected, the boxes were stored on the 17 lanes each lane would have a code for that stores requirement (entered by the controller), the 17 lanes would accumulate the required number of boxes when the pick for that consignment was complete the lane would release them and mix with others down to the next floor where again they were sorted into 6 lanes & stackers ready for moving into the lorries, seems a bit daft sorting then mixing then sorting but logistically made sense to make full use of the time and lorry loading slots.