PLC Pie Guy

Member

OP

Hey all.

Firstly, I thank you for assistance in this matter. And the answer to your question is yes, this is an L35E version 20.13 controller.

I need to read these posts a little more carefully right now.. I appreciate any advice one can give me with this.

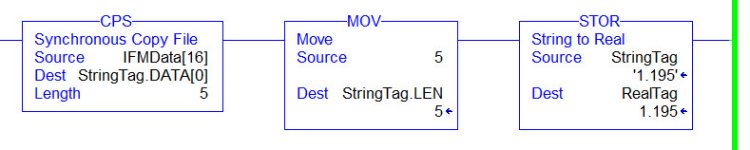

These are values coming from a vendor device. SINT is the type.

There was one other question regarding the string position.. The decimal will always be in the same place with the same number of digits on both sides.

Thankyou

I must correct this statement. I had two projects open when writing this and I accidentally put the wrong processor here. Its actually an L45 with V20.18.

Thanks