I need help in making an up/down counter using a rotary encoder. How do I program the plc to know whether the shaft is turning clockwise or counter clockwise to make the counter go up or down? I plan on using a 6 pulse/rev. encoder with a 2 channel square wave. Channel A leads channel B by 90 degrees. Any help is appriciated. Thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Idec micro 1 using encoder as up/down counter

- Thread starter b.nelson

- Start date

elevmike

Member

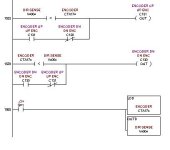

There are many ways to do this.

I do it by loading the counter value into a mem location. This would be done on a run above the counter.

On a rung after the counter compare the counter valve with the previous count taken before the counter. This will provide you with direction.

I do it by loading the counter value into a mem location. This would be done on a run above the counter.

On a rung after the counter compare the counter valve with the previous count taken before the counter. This will provide you with direction.

elevmike

Member

HSC

Hi

When i am using incremental encoder with PLC .mitsubishi FX2N for example .I just connect the encoder A ,B channels to the appropirate high speed inputs and i use one of the specified high speed counters in the plc.

The HSC counter automatically count the pulses up when the the encoder turn CW .and count it down when the encoder turn CCW.

Is your encoder is incremental one ?

Hi

When i am using incremental encoder with PLC .mitsubishi FX2N for example .I just connect the encoder A ,B channels to the appropirate high speed inputs and i use one of the specified high speed counters in the plc.

The HSC counter automatically count the pulses up when the the encoder turn CW .and count it down when the encoder turn CCW.

Is your encoder is incremental one ?

What is an icremintal encoder?? I am looking at an encoder in a digi-key catalog that has 2 square wave outputs that are out of phase by 90degrees...channel a. leads channel b. by 90 degrees. I dont see any of the encoders that are described as encrimental.

thanks, b.nelson

thanks, b.nelson

elevmike

Member

You have a quadature encoder..Get it Quad as in 1/4 or 25%... 90 deg is 25% or 1/4 of a full circle 360, etc etc..

Do they still make Micro 1 PLCs? These things are not very capable compaired to what's available today. What's your application?

Are you using that IDEC Dos stuff? Boy talk about a test in fortatude!

Good Luck,

Mike.

Do they still make Micro 1 PLCs? These things are not very capable compaired to what's available today. What's your application?

Are you using that IDEC Dos stuff? Boy talk about a test in fortatude!

Good Luck,

Mike.

I have several of these plc's available to me at no cost. I work in a machine shop and I am building a horizontal boring machine. The traverse on the table needs to rapid traverse in between cuts and slow down at each cut. I am looking for an inexpensive way to set the start/stop points of each cut. I could use prox./limit switches however, I would like to do it with an encoder...less expensive...less junk hanging off the side of the machine. I can buy the encoder I have described for less than $3.00. I cant buy a prox. switch for under $50.00 and I would need several of them as there are several cut locations on each run. I have a very limited budget to work with. Here is the specs. on the encoder I am looking at:

output: 2-bit gray code, Channel A leads Channel B by 90degrees electrically turning clockwise: 6 pulses per revolution.

Closed Circuit resistance: 2 ohms max.

Open circuit resistance: 100k ohm min.

Contact rating: 10milliamp @ 10vdc or .1w max.

Contact bouce @ 15 rpm: 5 milliseconds max.

Operating RPM: 120 max.

Life: 100,000 cycles

Thanks,

b.nelson

output: 2-bit gray code, Channel A leads Channel B by 90degrees electrically turning clockwise: 6 pulses per revolution.

Closed Circuit resistance: 2 ohms max.

Open circuit resistance: 100k ohm min.

Contact rating: 10milliamp @ 10vdc or .1w max.

Contact bouce @ 15 rpm: 5 milliseconds max.

Operating RPM: 120 max.

Life: 100,000 cycles

Thanks,

b.nelson

elevmike

Member

Are you using FA2Sys / FA2Mon? or a hand held programmer? What kinda resolution per inch are you seeking to acheave? 6 ppr is not what one would call high resolution. Where did you get an encoder for 3 bucks?

The code I posted earlier is for a DL240 PLC (AutomationDirect). Also my post only addresses direction sensing since I had assumed that you had the counter already down pat.

I have the software for the Micro 1 but I have not used it in years, and I dont have a Micro 1 manual anymore.

If you have a manual, look up the UP/ Down counter function. Actually this is a small manual, so read the whole thing. After you know a little more about the Micro 1, and the insturction set, it might be easer for someone to help with the code.

Mike

The code I posted earlier is for a DL240 PLC (AutomationDirect). Also my post only addresses direction sensing since I had assumed that you had the counter already down pat.

I have the software for the Micro 1 but I have not used it in years, and I dont have a Micro 1 manual anymore.

If you have a manual, look up the UP/ Down counter function. Actually this is a small manual, so read the whole thing. After you know a little more about the Micro 1, and the insturction set, it might be easer for someone to help with the code.

Mike

I will be using the winLDR software using a laptop and serial link cable. I am seeking a resolution of 0.03" The resolution is not critical. I could even use a timer function, but if we change the spindle speed then we would have to reprogram the time per cut.

I have very little experience with plc's. I have not used a Micro 1 but I have a manual coming in the mail and I will be studying it. I was just needing a place to start for programming an up/down counter using an encoder. I will get the manual and play with the plc and see if i can make something work. Thanks for at least getting me headed in the right direction. Although, I dont think the plc has a 2 channel input for a 2 channel encoder. I was hoping to find a programing solution and not a new piece of equipment. I dont have the software yet either, I have not got a PO from management yet for it so when I get it I will be learning as I go.

Thanks for the info.

Brandy

I have very little experience with plc's. I have not used a Micro 1 but I have a manual coming in the mail and I will be studying it. I was just needing a place to start for programming an up/down counter using an encoder. I will get the manual and play with the plc and see if i can make something work. Thanks for at least getting me headed in the right direction. Although, I dont think the plc has a 2 channel input for a 2 channel encoder. I was hoping to find a programing solution and not a new piece of equipment. I dont have the software yet either, I have not got a PO from management yet for it so when I get it I will be learning as I go.

Thanks for the info.

Brandy

Oh, the encoders I am looking at are discrete devices. I am looking in a Digi-key electronics catalog. The paticular encoder I am looking at is a BOURNS 9mm square/sealed encoder Digi-Key part #3315c-001-006-nd. the 1 piece price is $2.77, 10 for $2.45, 50 for $2.06, 100 for $1.76. they are at the bottom of page 927 in cat.#TO33. If you have a Digi-Key catalog please look at this device and see if you think it will work.

Thanks,

Brandy

Thanks,

Brandy

elevmike

Member

I've got some very bad news for your Brandy. The Micro 1's instruction set is very limited and does not have an up/down counter. No INC or DEC, No ADD or SUB either! The micro 1 is what some would refere to as a "programmable relay". With very limited capabilities.

Additionally the "encoders" you picked out do not incorperate a driver circut either. They are intended as Board Components so that you can design an encoder circuit from the ground up.

Suggestion: Either breakdown and buy prox switches , or a PLC such as the DL-05 , and a proper encoder .

You will pay a little more than $300.00 for the PLC encoder, and programming software. You might find it well worth the investment.

Now I remember why we stoped useing the Micro 1.

Mike.

Additionally the "encoders" you picked out do not incorperate a driver circut either. They are intended as Board Components so that you can design an encoder circuit from the ground up.

Suggestion: Either breakdown and buy prox switches , or a PLC such as the DL-05 , and a proper encoder .

You will pay a little more than $300.00 for the PLC encoder, and programming software. You might find it well worth the investment.

Now I remember why we stoped useing the Micro 1.

Mike.

elevmike

Member

OOPS! I was wrong! Counter s 45 & 46 are up/down counters.

However I would still reccomend going with a more powerfull PLC.

Mike.

P.S. You can download the Micro 1 manual here .

However I would still reccomend going with a more powerfull PLC.

Mike.

P.S. You can download the Micro 1 manual here .

randylud

Member

A bit of clarification

res·o·lu·tion:

The fineness of detail that can be distinguished in an image, as on a video display terminal. Or the fineness of detail that can be achieved by a 6pulse/rev encoder.

res·o·lu·tion:

The fineness of detail that can be distinguished in an image, as on a video display terminal. Or the fineness of detail that can be achieved by a 6pulse/rev encoder.

So when does resolution become critical in your business? If getting only as close as the nearest 1/32" is not close tolerance then what is? +/- .001"? Better give Mike's suggestions some thought and get an encoder that will give you several hundred pulses/rev. Then having a good PLC, you will be able to do pretty much what you need to do.I am seeking a resolution of 0.03" The resolution is not critical.

Mtn_Bkng_Dave

Member

Ok I'm gonna add 2 words to this thread.

DESTROYED TOOLING!

Without a true high speed quadrature input on the PLC this is more than likely what you are going to experience. Are you planning on attaching the encoder to the lead screw that is moving the boring head? You need to look at some critical numbers in this application to see if this is even feasible.

1. Desired rapid traverse speed in "/Min

2. Lead Screw pitch in TPI

3. Encoder resolution Pulses/Rev

Use this information to determine the maximum frequency of the encoder input. I think you are going to find that this far exceeds the maximum input frequency obtainable by the inputs you are planning on using. A good rule of thumb is to not exceed an input rate faster than 3 times the scan time to insure accurate counting. There are some tricks to work around this but im not sure if the Micro 1 will allow it like timed interrupts etc.

Do a litte research because a CNC crash is not a pretty site....Just ask my poor Mori Seiki lathe with the cracked tailstock!

Good luck,

Dave

DESTROYED TOOLING!

Without a true high speed quadrature input on the PLC this is more than likely what you are going to experience. Are you planning on attaching the encoder to the lead screw that is moving the boring head? You need to look at some critical numbers in this application to see if this is even feasible.

1. Desired rapid traverse speed in "/Min

2. Lead Screw pitch in TPI

3. Encoder resolution Pulses/Rev

Use this information to determine the maximum frequency of the encoder input. I think you are going to find that this far exceeds the maximum input frequency obtainable by the inputs you are planning on using. A good rule of thumb is to not exceed an input rate faster than 3 times the scan time to insure accurate counting. There are some tricks to work around this but im not sure if the Micro 1 will allow it like timed interrupts etc.

Do a litte research because a CNC crash is not a pretty site....Just ask my poor Mori Seiki lathe with the cracked tailstock!

Good luck,

Dave

Eric Nelson

Lifetime Supporting Member + Moderator

I see we have ANOTHER Nelson!...

As everyone else is saying, 6PPR just ain't gonna cut it (no pun intended).

If you're dead set on using these ancoders, consider gearing them to the drive so they spin a lot faster. Oh wait, they're only rated for 120RPM...

These are simple the wrong encoders for this application...

beerchug

-Eric

As everyone else is saying, 6PPR just ain't gonna cut it (no pun intended).

If you're dead set on using these ancoders, consider gearing them to the drive so they spin a lot faster. Oh wait, they're only rated for 120RPM...

These are simple the wrong encoders for this application...

beerchug

-Eric

Similar Topics

Hello,

I am a new member. I use an old automatic wood oven. Its controlled with a IDEC Micro-1 PLC. There is now a mistake.

When I switch on the...

- Replies

- 1

- Views

- 1,095

Joe here from Palm Gaming- hoping to find some help here-

we run a custom made heat press- we make ***** chips for casinos- the press has the orig...

- Replies

- 10

- Views

- 7,312

I have a machine that is new to our plant that has a Idec Micro 3 FC2A-C24A1 processor. Does anyone know if WindLDR ver 4.2 will talk to this...

- Replies

- 3

- Views

- 3,658

I am working on a project and was curiouse if anyone knew or knew where i could find the schematics for the Micro-1 and Micro-1 expansion plc's...

- Replies

- 5

- Views

- 1,966

Hello there!

Need help for micro-1 idec plc interface pinout. Units were obsolete and it seems quite hard to find means to access such PLC...

- Replies

- 5

- Views

- 3,429