I agree with Ronnie, however, even though I have unplugged & plugged in on Mitsubishi probably thousands of times and never had a problem, to go to a site and on that one occasion something goes wrong that's a worry, however, powering down & up again is more likely to cause a problem, i.e. a spike at the moment you power up again, power supply failure (most PSU failures occur on power up).

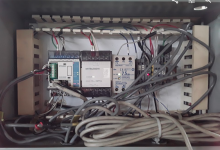

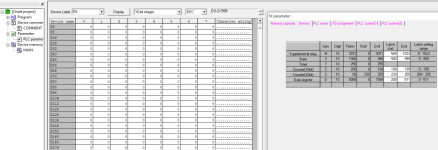

It looks like from the pics that this has a 422/485 BD add on board for the communications to the inverters, The settings for the protocol are in the 8000 range of registers (8000 > on are for things like clock, coms settings etc.

Just a heads up on communication with GX Dev. The FX if powered down defaults to 9600 etc. however the settings for the add on board are retained (battery or NVRam permitting) this is not a problem for most HMI's I have used and most people set the coms at the default, however, GX and some HMI's are capable of forcing the plc to other baud rates when you set the connection in GX even if you set it at a different Baud rate it will force the PLC to communicate at that rate, if the HMI is not capable of doing this operation then it will not communicate until you re-boot the PLC. I came across this when connecting an OPC server at 56k to the programming port it would not communicate, however, if I first connected GX at that rate then plugging in the OPC server worked, however, when powered down the plc reverted back to 9600, so I had to keep the server at the default.

It would be a good idea to download the add on board manual that shows typical set up of the board, this is often done within the plc code with TO/FROM instructions to the registers Here is a link to the manual

http://dl.mitsubishielectric.com/dl/fa/document/manual/plc_fx/jy992d69901/jy992d69901e.pdf

Note: section 4 gives the registers used and some examples, it's a bit lengthy but covers all versions of the add on boards.

If the original inverters are Mitsi i.e. 500, then upgrading them to the 700 it may not require any mods in the PLC as the 500 & 700 are so similar. but I have never done it.