risk

Member

New to group

I've seen well pump controllers with analog circuits that pump till sensing a current drop then start a timer.

Seems an opportunity to use a PLC to sense high water and latch a relay to pump until unloading is sensed by current drop and then deactivate the coil. This would eliminate the low level float switch.

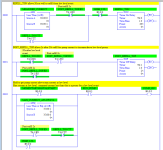

I'm starting from scratch but happen to have a lot of Siemens equipment on hand. Was tempted to offer my code here as a starting point for discussion but that would be embarrassing.

As for the input. I was thinking of a sense coil into a/d module and tuning in S7 but wonder if there is a turn key module for this problem. I prefer to use modular hardware for learning.

Thanks for helping out a beginner.

I've seen well pump controllers with analog circuits that pump till sensing a current drop then start a timer.

Seems an opportunity to use a PLC to sense high water and latch a relay to pump until unloading is sensed by current drop and then deactivate the coil. This would eliminate the low level float switch.

I'm starting from scratch but happen to have a lot of Siemens equipment on hand. Was tempted to offer my code here as a starting point for discussion but that would be embarrassing.

As for the input. I was thinking of a sense coil into a/d module and tuning in S7 but wonder if there is a turn key module for this problem. I prefer to use modular hardware for learning.

Thanks for helping out a beginner.