TheWaterboy

Lifetime Supporting Member + Moderator

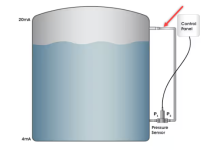

I have an issue where I have a DP transmitter on a horz tank reading liquid level.

Due to odd and unforeseen circumstances the tank filled to the top above where the transmitter is connected and so it allowed water into the low side impulse line to the Transmitter which threw everything off of course.

Is there a readily available solution to this? I came up with the idea of using a hydrophobic filter, a membrane style gauge isolator, a water trap like those on compressed air lines, and simply taking the impulse line above the top of the tank to prevent the siphon from ever occurring, like an inverted P-Trap.

I can’t change the pressure tap location so I have to deal with what I have.

But before I fall back on my training from the Rube Goldberg School of Engineering, I wonder if there is already a bolt in solution available for such conditions?

Due to odd and unforeseen circumstances the tank filled to the top above where the transmitter is connected and so it allowed water into the low side impulse line to the Transmitter which threw everything off of course.

Is there a readily available solution to this? I came up with the idea of using a hydrophobic filter, a membrane style gauge isolator, a water trap like those on compressed air lines, and simply taking the impulse line above the top of the tank to prevent the siphon from ever occurring, like an inverted P-Trap.

I can’t change the pressure tap location so I have to deal with what I have.

But before I fall back on my training from the Rube Goldberg School of Engineering, I wonder if there is already a bolt in solution available for such conditions?