AutomationTechBrian

Lifetime Supporting Member

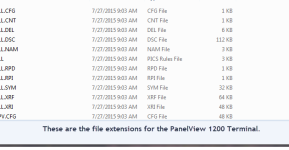

This is a question about the old Panelview file on a legacy machine.

I got a call from a customer asking me if I could help him upgrade the PLC and HMIs on 3 machines. He said the Allen Bradley PLCs were from SLCs from 1997. That sounds good.. I've got Logix 500. He said the HMIs are old Panelviews... pretty sure that means Panelbuilder32, which I don't have, but might be able to borrow from a customer.

But the part I get hung up on is upgrading the HMI. Is the compiled file on the Panelview any good for reading the tags? I don't think he has the source file.

I got a call from a customer asking me if I could help him upgrade the PLC and HMIs on 3 machines. He said the Allen Bradley PLCs were from SLCs from 1997. That sounds good.. I've got Logix 500. He said the HMIs are old Panelviews... pretty sure that means Panelbuilder32, which I don't have, but might be able to borrow from a customer.

But the part I get hung up on is upgrading the HMI. Is the compiled file on the Panelview any good for reading the tags? I don't think he has the source file.