I have a system where I am planning to add a significant amount of alarming, and want to do it with a memory efficient method that executes as quickly as possible. I am using an Allen Bradley PLC-5.

The general behavior that I am looking for is to have 3 "levels" for each alarm (based on time). As soon as the alarm conditions are true, an "Error Exists" bit should be energized. At some point in time after that, a "Warning Exists" bit should be energized. At some point in time after that, a "Fault bit" should be set. Both the error and warning bits should clear when the input conditions clear. A fault will require the operator to manually reset the fault bit from the HMI.

The times used for each transition (Error to Warning to Fault) will potentially vary for each specific alarm (depending on severity and/or system response time).

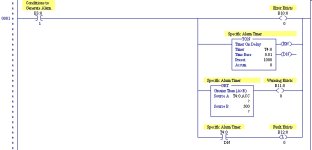

Here is a general template that I came up with, but I can't help thinking that there has got to be a faster, less memory intensive way of getting the same behavior. Any thoughts?

Thanks,

Marc

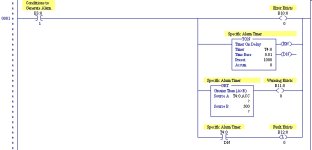

The general behavior that I am looking for is to have 3 "levels" for each alarm (based on time). As soon as the alarm conditions are true, an "Error Exists" bit should be energized. At some point in time after that, a "Warning Exists" bit should be energized. At some point in time after that, a "Fault bit" should be set. Both the error and warning bits should clear when the input conditions clear. A fault will require the operator to manually reset the fault bit from the HMI.

The times used for each transition (Error to Warning to Fault) will potentially vary for each specific alarm (depending on severity and/or system response time).

Here is a general template that I came up with, but I can't help thinking that there has got to be a faster, less memory intensive way of getting the same behavior. Any thoughts?

Thanks,

Marc