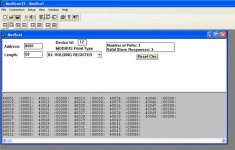

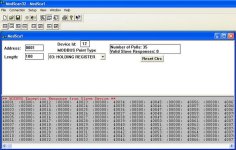

Is anyone out there who know how to configure PLC TSX3721 Micro (v5.1) so my PC can read modbus from it. I have a Modbus Tester but it can't see my PLC-system. I'm not sure how to set up the PLC device ID (but I think the Id number is 1). Maybe I need to do some command that sends out modbus to my PC, is that possible. I am pretty sure that the connation between my PC and theTER-port on the PLC is right, pin 5 and 7 connect together (have a test program on my PLC that sends Character-string over to my PC system and it works).

I've never worked with Modbus but I gather that the "% MW: x" variables in TSX3721 is the same as modbus memory locations 40000x, but how do I read that memory locations from the PLC system and put it in modbus-memory locations. There some talk that it needs to install a PCMCIA Modbus in to TSX3721, others talk about TSX3721 v3.3> can talk modbus, and I have v5.1.

I am trying to connect TSX3721 Micro v5.1 with Citec/Scada v7.2 through the serial on PC machine.

I've never worked with Modbus but I gather that the "% MW: x" variables in TSX3721 is the same as modbus memory locations 40000x, but how do I read that memory locations from the PLC system and put it in modbus-memory locations. There some talk that it needs to install a PCMCIA Modbus in to TSX3721, others talk about TSX3721 v3.3> can talk modbus, and I have v5.1.

I am trying to connect TSX3721 Micro v5.1 with Citec/Scada v7.2 through the serial on PC machine.