Lancie1 said:

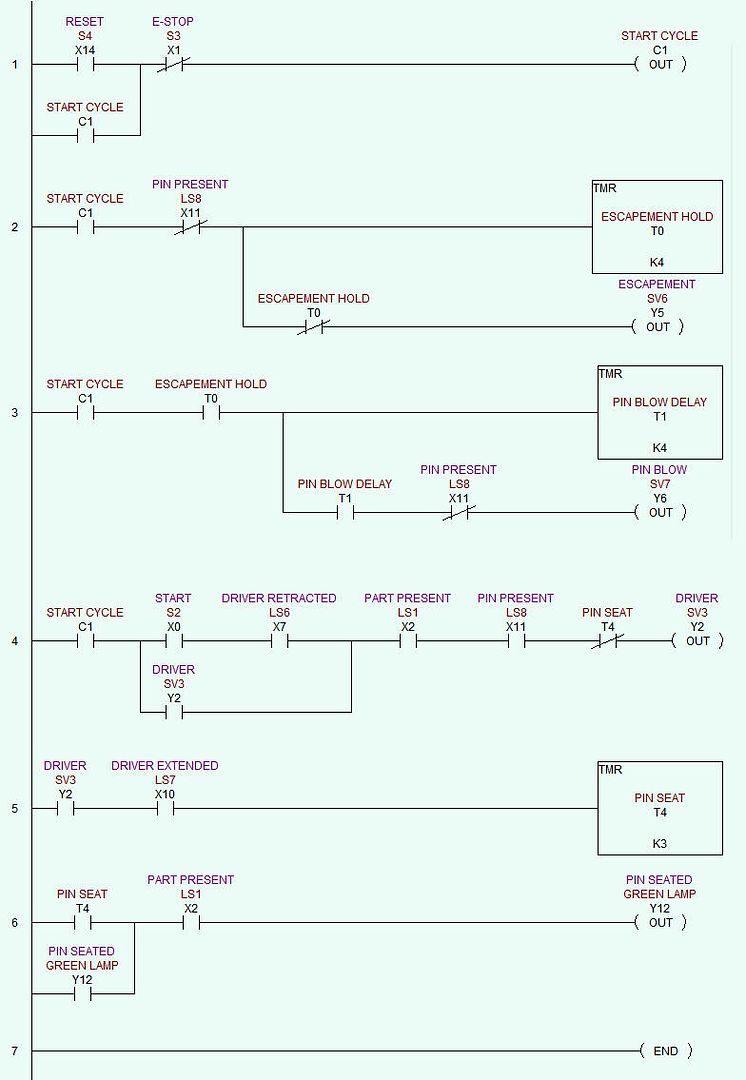

I think my new timer T2 is still the best solution.

I think it would make sense if the escapement was prone to missing cycles, and could be corrected by re-initiating the sequence. But this hasn't proven to be the case. It is always something upstream of the escapement mechanism. To date, there has not been a single problem with the pin-feed sequence (save for the present issue) where re-cycling the escapement would have corrected the problem. One time, a small metal chip got caught in the feeder track between the bowl and escapement, which prevented the pins from reaching the escapement. Another time, an operator had placed something heavy on the enclosure which covers the bowl. The weight actually bore down on the bowl, compressing the rubber mounts, and causing a misalignment between the discharge track and escapement inlet. But the most common reason that the pin-feed cycle "fails" is because they let the bowl run out of pins. The operators know as soon as they hear that hiss of air, with no pin being delivered, to shut down the machine and check the bowl.

Still, the repeating timer might be a good idea, except that in some instances it might exacerbate an existing problem. For example, if the escapement works perfectly, and delivers the pin to the air stream, but for some reason the pin hangs up between the escapement and nosepiece, the PLC will keep sending pins into the blow tube. Presumably, until it fills up with pins.

My plan for now is to try it out with the start-up rung as shown above. Hopefully this will solve the problem. Thanks for all your help, Lancie!

Paula