Hi guys! really enjoyed reading the threads about the different "languages" used in programming PLC... learned a lot!

anyway, i just want to ask for sage advice on CoDeSys programming... since I come from AB background (and a little Schneider) which means im used to drag/drop, index addressing, automatic file type conversion, and all those silly things that made my life soo much easier before!lol

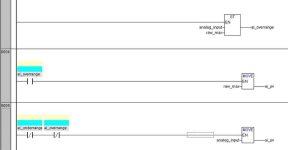

Right now I am working for a company that uses CoDeSys and Siemens software, but Id like to learn codesys first since that is what we mostly use... I have already explored the software and found out that even the most "basic" logic does not have the same result... like in programming interlocking contacts, I found out that once you turn a contact to a "true" state, it remains that way unless you right another ladder to make it false (more like "IF THEN" statement and you have to put the "ELSE" statement to make it go "false" again). also in the use of SET/RESET contact, you can use RESET before SET without having problem in the logic unlike in AB where Latch will not turn on if Unlatch is put before it (due to the program cycle). Ladder logic is reaalllly limited in codesys so im trying to learn structured text and the other languages but im most comfortable in ladder.

Any other things I have to watch out for when using ladder logic?

anyway, i just want to ask for sage advice on CoDeSys programming... since I come from AB background (and a little Schneider) which means im used to drag/drop, index addressing, automatic file type conversion, and all those silly things that made my life soo much easier before!lol

Right now I am working for a company that uses CoDeSys and Siemens software, but Id like to learn codesys first since that is what we mostly use... I have already explored the software and found out that even the most "basic" logic does not have the same result... like in programming interlocking contacts, I found out that once you turn a contact to a "true" state, it remains that way unless you right another ladder to make it false (more like "IF THEN" statement and you have to put the "ELSE" statement to make it go "false" again). also in the use of SET/RESET contact, you can use RESET before SET without having problem in the logic unlike in AB where Latch will not turn on if Unlatch is put before it (due to the program cycle). Ladder logic is reaalllly limited in codesys so im trying to learn structured text and the other languages but im most comfortable in ladder.

Any other things I have to watch out for when using ladder logic?