Hi,

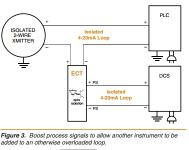

I have 10 sensors whose output is 4-20mA connected to a S7-200 PLC. This is an existing system. Now, I want to take this 10 sensors output to another PLC also. How to do this? Should i split the sensor output or I need to loop it from S7-200? Is there any problem to do like this?

Thanks,

Randheer

I have 10 sensors whose output is 4-20mA connected to a S7-200 PLC. This is an existing system. Now, I want to take this 10 sensors output to another PLC also. How to do this? Should i split the sensor output or I need to loop it from S7-200? Is there any problem to do like this?

Thanks,

Randheer