Anastasis

Member

Hello everyone... I am new to the PLC world and I would really love it if you gave me some interest about the problem I am dealing with for about 1-2 weeks. It's about a paper I have to deliver for school until the 12 of the month.

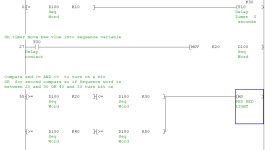

I am doing a traffic light controller using plc especially STL programming.

I want to make a cycle of 2 traffic lights one for the vehicles and the other for (you guessed it right) the pedestrian.

I will need one button (saying I0.1 ..) only for the sequence to begin(NOT a pedestrian button as I saw many times on the internet about other papers..)

Firstly, I want my green light for the cars and red light for the peds to be turned on even thoug I have not pressed the button.

The sequence i like to do ONLY WHEN I PRESS THE BUTTON is the following:

1) GR_CAR & RED_PED = 15s

2) YEL_CAR & RED_PED = 5s

3) RED_CAR & GR_PED = 4s

4) RED_CAR & RED_PED = 3s

5) AND IN THE END I WANT TO HAVE GR_CAR & RED_PED AGAIN BUT THIS TIME FOR 10 seconds.

This is my cycle and i want that to happen all over again when it ends (as you can imagine).

Pleaseeee If you have something in mind let me know with a response cause i really need some help over here....

Try not to laugh too much at me I am new...

Thanks in advance!!

I am doing a traffic light controller using plc especially STL programming.

I want to make a cycle of 2 traffic lights one for the vehicles and the other for (you guessed it right) the pedestrian.

I will need one button (saying I0.1 ..) only for the sequence to begin(NOT a pedestrian button as I saw many times on the internet about other papers..)

Firstly, I want my green light for the cars and red light for the peds to be turned on even thoug I have not pressed the button.

The sequence i like to do ONLY WHEN I PRESS THE BUTTON is the following:

1) GR_CAR & RED_PED = 15s

2) YEL_CAR & RED_PED = 5s

3) RED_CAR & GR_PED = 4s

4) RED_CAR & RED_PED = 3s

5) AND IN THE END I WANT TO HAVE GR_CAR & RED_PED AGAIN BUT THIS TIME FOR 10 seconds.

This is my cycle and i want that to happen all over again when it ends (as you can imagine).

Pleaseeee If you have something in mind let me know with a response cause i really need some help over here....

Try not to laugh too much at me I am new...

Thanks in advance!!