FrankBerends

Member

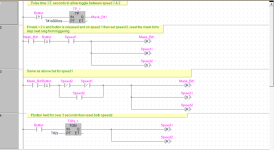

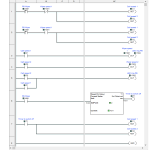

For my boat I'm designing a whole new control panel. Every piece of equipment to be controlled with just one (flip-flop) button.

For the windscreen wiper, I'm almost there. Just one little annoying problem to solve. The way it should work:

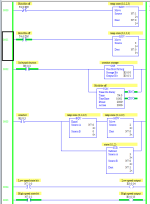

Momentary Push Button x1,

push 1 -> starts with speed 1

push 2 -> toggles to speed 2

push 3 -> toggles to speed 1

push 4 -> toggles to speed 2

and so on, until it stops raining..:

keep push button pressed for 2 seconds -> wiper switches off

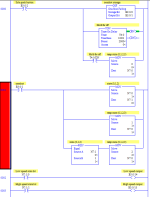

What I've done is almost good, but at that 2 seconds push, it instantly toggles speed before it switches off. I know why , but I don't know how to prevent that last toggle. Anyone that has a solution?

, but I don't know how to prevent that last toggle. Anyone that has a solution?

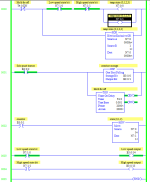

I'm quite a novice with PLC, so my setup is very straightforward, but at least this is simple to understand (for me).

For the windscreen wiper, I'm almost there. Just one little annoying problem to solve. The way it should work:

Momentary Push Button x1,

push 1 -> starts with speed 1

push 2 -> toggles to speed 2

push 3 -> toggles to speed 1

push 4 -> toggles to speed 2

and so on, until it stops raining..:

keep push button pressed for 2 seconds -> wiper switches off

What I've done is almost good, but at that 2 seconds push, it instantly toggles speed before it switches off. I know why

I'm quite a novice with PLC, so my setup is very straightforward, but at least this is simple to understand (for me).