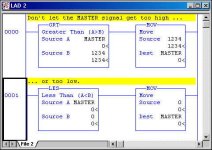

I have been given the task of scaling two analogue outputs to drive two conveyors.The setpoints are set in the scada system. The first analogue output will be the master from the set point, the second analogue out will be slaved and has got to be scaled slower than the first. I am obviously writing the analogue outputs to two inverters, I cannot use the fist set point as a master and then slave the second on the inverters, it has to be done by two outputs from the plc. The plc is Allan Bradley SLC 505 and the Skada is RS View. This is my first ever question, I hope someone can understand it and will reply!!

Analogue scaling

- Thread starter john clay

- Start date

Similar Topics

Hi, I have a ControlLogix system with 1756-IF16 analogue inputs. I can't scale the inputs at the card as there is a requirement to facilitate...

Hello guys

I am just wondering do I need to set up each channel configuration, including enabling the channel , ranging … if I have already...

There have been a number of posts asking about scaling so I thought this may help.

The formula is:

Out := ((Variable_In - ZeroIn) / (SpanIn -...

Hi,

I have an application with a load cell where I need to log the load cell output, into a small/internal data logger. But I also want the...

Hello there

I am having trouble scaling my analogue input signals.

If I use engineering units and use the RAW scale as 4000-20000 everything is...