thedolanduck

Member

Hello everyone!

I have a Schneider M241 as master of a CAN network with several encoders and whatnot, everything is working fairly well. Now, recently I had to add a new device to the network, an IMET M880 Zeus2 waist belt transmitter, which I did and is working OK. Except for one thing: I cannot write to its display (it's an optional feature to include a display, but my client requested one).

See, IMET provided me with an EDS file, so all I did in my SoMachine project was install the device using said file through the Device Repository, add it to my CANOpen bus, and voilÃ*, I had all my variables automatically mapped. All I did was put a name on them and add them to my logic.

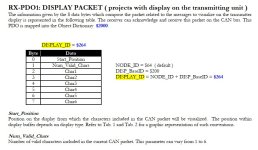

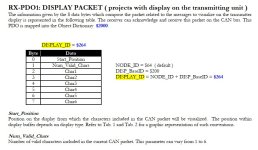

This worked wonders for all the Tx-PDO's, i.e. reading which joystick I am moving and which way, etc. But apparently, for the Rx-PDO's (a.k.a writing to the display) it does not. I follow the manual's instructions (see image no. 1) and nothing happens.

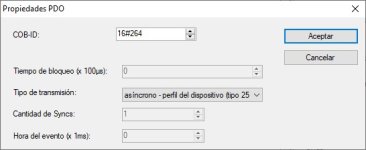

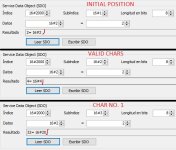

Now, I used a CAN Interface for PC and the Maintenance Tool software by IFM to connect my laptop to the CANbus. I started monitoring it, and came to realize that not one message was sent to the COB-ID 264H, which explained why nothing was showing up in the display. Then, I used said software to manually write the HELLO word, and it worked! (See image no. 2)

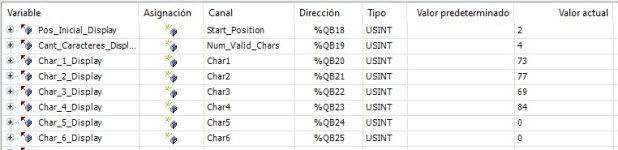

Obviously, then, I am doing something wrong in the PLC part. From what I understand, all I have to do is move HEX values to the corresponding USINT mapped variables, nothing fancy, but I must be missing something. In particular, I'm doing:

I also tried changing the Transmission Type in the PDO configuration from SoMachine, but none of the available options worked and I really don't know what else to try.

I apologize if this is too dumb, and I hope anyone of you know the answer. Thank you!

I have a Schneider M241 as master of a CAN network with several encoders and whatnot, everything is working fairly well. Now, recently I had to add a new device to the network, an IMET M880 Zeus2 waist belt transmitter, which I did and is working OK. Except for one thing: I cannot write to its display (it's an optional feature to include a display, but my client requested one).

See, IMET provided me with an EDS file, so all I did in my SoMachine project was install the device using said file through the Device Repository, add it to my CANOpen bus, and voilÃ*, I had all my variables automatically mapped. All I did was put a name on them and add them to my logic.

This worked wonders for all the Tx-PDO's, i.e. reading which joystick I am moving and which way, etc. But apparently, for the Rx-PDO's (a.k.a writing to the display) it does not. I follow the manual's instructions (see image no. 1) and nothing happens.

Now, I used a CAN Interface for PC and the Maintenance Tool software by IFM to connect my laptop to the CANbus. I started monitoring it, and came to realize that not one message was sent to the COB-ID 264H, which explained why nothing was showing up in the display. Then, I used said software to manually write the HELLO word, and it worked! (See image no. 2)

Obviously, then, I am doing something wrong in the PLC part. From what I understand, all I have to do is move HEX values to the corresponding USINT mapped variables, nothing fancy, but I must be missing something. In particular, I'm doing:

Code:

Start_Pos = 16#02;

Valid_Chars = 16#05;

Char_1 = 16#48;

Char_2 = 16#45;

Char_3 = 16#4C;

Char_4 = 16#4C;

Char_5 = 16#4F;I also tried changing the Transmission Type in the PDO configuration from SoMachine, but none of the available options worked and I really don't know what else to try.

I apologize if this is too dumb, and I hope anyone of you know the answer. Thank you!