Operaghost,

It took me a while, sheeesh...but I finally get it. It also makes complete sense. I have to see if I can fetch the other projects that contain the code for the other controllers. Thanks tons gents

If you can't "fetch the other projects that contain the code for the other controllers". then you can at least see the code and the tag databases, by performing an "upload" from the controller(s) into a new project(s) in your programming software.

For the L73 module it may be that the programmer selected to store the documentation in the controller as well (it's a new option from V21 upwards), otherwise you will just see plain undocumented code.

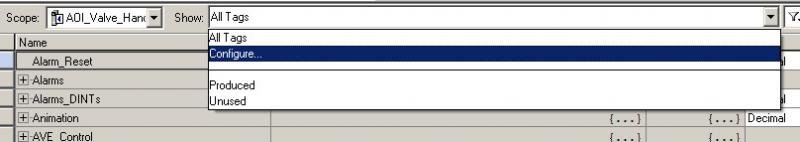

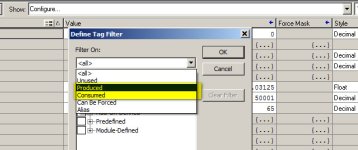

If you really want to get to the nitty-gritty of how the controllers are interacting, then in the tag-databases you can apply filters to the display to show only Produced or Consumed tags (unfortunately you can't do both at the same time). Look at the configuration of Consumed tags to see what data they are consuming, and from where. Mostly people use the same tag-names in both controllers as it helps when debugging, but it isn't necessary to do so.

Also look out for (search) MSG instructions. Any message that has a "Communications Path" of one of the other controllers name in the I/O tree is either reading from, or writing to, the other controller, depending on MSG configuration.